Product Description

Natural thatched tiles have many disadvantages, such as fire hazards, wind damage, insects and rot. Even if the initial cost is only a little lower than the synthetic product, the future maintenance cost is a nightmare. Our synthetic thatch tiles provides an easy way to build bars, beach resorts and zoos anywhere without worrying about maintenance costs.

The thatch tiles are made of high-quality environmental synthetic materials, using molds made from real thatch. This makes our products look exactly like natural products because of that durable, long-lasting and maintenance-free materials. You will be surprised to find that it can withstand the test of more than 20 years under the conditions of sea breeze, heavy rain, snowstorm, strong sunlight and general wear and tear, that will still maintaining an amazing appearance.

With colorful choices, you will be able to find a look that fits your design scheme.

| Products | Eaves Thatch Roof Tiles |

| Material | Synthetic Resin, PP, PE or PVC |

| standard size | 500*500mm/1000*600mm.Customer size is aviliable |

| Weight | 0.25KG-1.10KG |

| Types of leaves | flat, round bar |

| Color | Straw yellow, Brown , Black , Wheat yellow. Golden Yellow, Rotten Yellow,Rotten gery,Brown Yellow,Golden gray, Green, Turmeric Yellow ect and customerdesian color is aviliable |

Product Feature

Save installation time and cost: 6pcs/m2,

light weight, easy and fast installation, free maintenance, which save much installation

time and cost.

Excellent weather-resistance, sturdy and durable: Anti-UV, stable color, anti-bacteria, anti-acid alkali.

Well withstand harsh environment, temperature is -100℃~+70℃, lifetime up to 10~50 years.

High Safety: Fire-retardant. Hurricane resistance Level 12.

Beautiful and practical: The longer used, the more realistic and natural the color will be. Replace the real thatch, widely used

in various construction buildings.

Excellent tenacity and strength: Wind load deformation resistance, waterproof and seismic performance, all meet the requirements

of structural design.

Environment friendly and recyclable.

Fine workmanship: Professional craftsmen, good technology, create different standards, support customized.

Color Shows

FUGU Thatch Straw Roof Tiles can be many different type of colors. here just some colors for reference. And if any special required we accept the customer design. PE Resin Plastic Artificial Thatch Simulated Straw for Roof Tiles in Tourist Attractions

Workingshop

FUGU Building Material Group, specializing in producing and marketing green environment-friendly products for construction and municipal engineering projects, loaded at Hefei City, which is the capital of Anhui province, with production sites in Anhui, Jiangsu, Zhejiang, Hebei, Shandong and Fujian Provinces. PE Resin Plastic Artificial Thatch Simulated Straw for Roof Tiles in Tourist Attractions

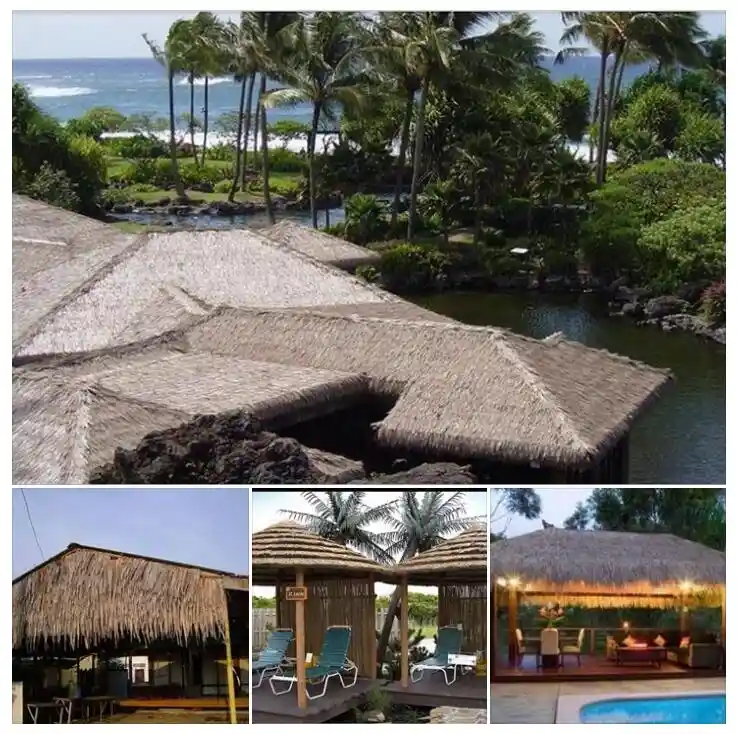

Projects

FUGU Thatch Straw Roof Tiles are made of PE/PPR/Nylon, is a new landscape ideal material for roof decoration, with features of waterproof, anti-corrosion, protect against termites, insect prevention. The most important advantage is that it can be used for more than 20 years. Class A Fire-retartant product is available for your choice.

Widely applications in hotels in the Garden District, the zoo, theme parks, restaurants or bars in the outdoor pavilion,

landscape , Spa resorts, parks and scenery, resorts, bus stations, recreation pavilion, high-end residential building, villas District, museums, seaside bars, beach grill bar, water sports pavilion, tropical-style venues and so on.

Installation

1.Prepare waterproof layer first.

2.installkeels horizontally and vertically, the keels can be square tube, C steel or anti-corrosion wood. The vertical distancefor the keel is about 40cm. lf installed on steel wire mesh, suggest fasten thatch roof tiles to steel wire mesh by wire rope

3.The first row drops 30cm as eaves.

4.The distance between the first row and the second row is 10cm, Keep the two rows closer, make roof looks thick.

5.The distance between the second row and the third row is 15cm

6.The distance between the third row and the fourth row is 20cm.

7. The distance between the fourth row and the fifth row is 25cm

8. The rest distance is 30cm since the fifth row.

9. A little messy will looks better. The thatch need to naturally drooping to become

as the rainwater flowing direction.

10. Ridge Treatment: Folding the Synthetic Thatch Roof Tile and fix.