India WPCL 6X600MW Subcritical Coal-Fired Power Plant Project

ملخص المشروع:

India WPCL6X600MW power plant new construction project is located in Chhattisgarh state, India, the design of the single unit capacity of 600MW, the total capacity of 6x600MW, sub-critical coal-fired condensing unit. The main coal used in this project is Indian high ash, low calorific value low quality bituminous coal with maximum particle size less than 300mm and packing density 0.8t/m3. The designed coal comes from Morga Coal Mine in Korba District and GarePalma-Sector-III Coal Mine in Raigarh District, which is less than 150km away from the power plant, and transported by bottom-driven trucks.

The coal is transported into the plant by bottom drive trucks, and there are two 240m long slit-type coal chute unloading trenches, with double 1400mm conveyors in the lower part of the plant, and each conveyor is equipped with two sets of impeller feeders, making a total of eight sets, each with an output of 800~1200t/h. The impeller feeders and gravity-type coal chute baffles are arranged in the slit-type coal chute unloading trenches. India KMPCL6X600MW sub-critical coal-fired power plant has six coal yards at the top of the plant, each with a design capacity of 760,000 tonnes. There are three bucket wheel stacker reclaimers in the coal yard, and the stacking and reclaiming capacity is 1800t/h in parallel arrangement.

The entire coal conveyor system of this project is divided into two sets of coal transport systems with 41 belt conveyors (excluding the tipper system) and one set of coal transport system for 3x600MW units. Except for C-12, C-13 and C-14 belt conveyors, all other belt conveyors are indoor arrangement. Each set of belt conveyor of coal transport system is arranged in A, B or C, D double road, one road running, one road standby, and each of them has the condition of double road running. The belt conveyor of coal conveying system (except C-2ABCD) has a belt width of 1400mm, belt speed of 3.0m/s and output capacity of 1800t/h. The belt width of the four belt conveyors of C-2ABCD is 1800mm, the belt speed is 2.0m/s and the output capacity of the two sets of coal conveying system is from the fixed end of the main plant, and the coal bunker level adopts the electric double-side pearly unloader to dispense the coal to the raw coal bunker.

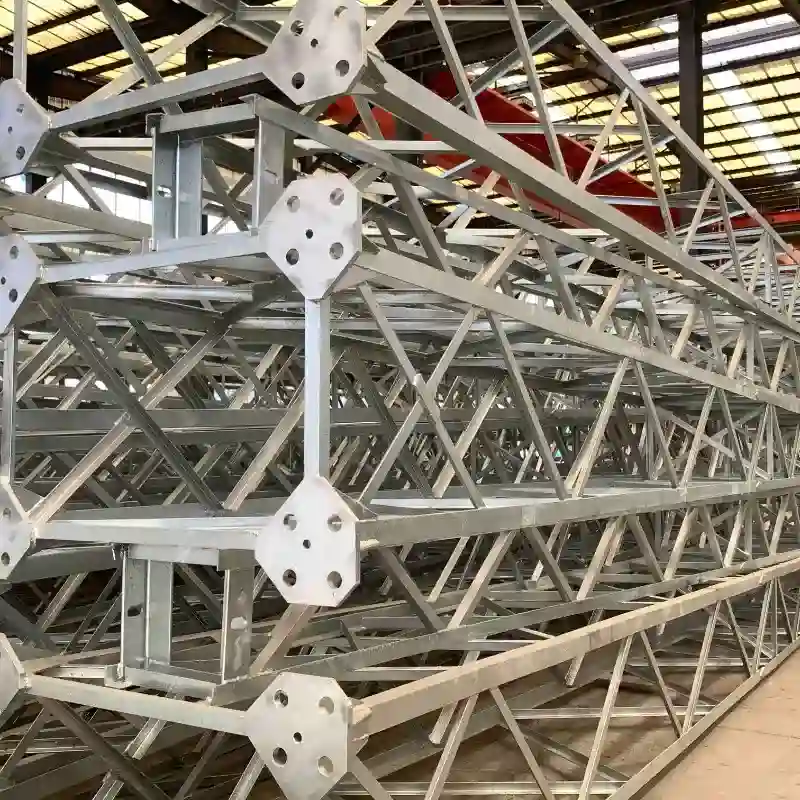

The project uses 12,000 tonnes of steel.