Nanjing Lukou airport stage-Ⅱ

Nanjing Lukou International Airport, located in Lukou Street, Jiangning District, Nanjing City, Jiangsu Province, is the gateway to Jiangsu Province and Nanjing City, is a major national trunk airport, a class of air ports, the main cargo airport in East China, and Shanghai Hongqiao Airport, Pudong Airport as each other's backup airports, is a national large-scale hub airports, China's air cargo centers and express distribution centers, the National Regional Transportation Hub.T2 terminal opened on 12 July 2014, is the main building plus promenade front domestic and international integrated terminal building, designed for an annual capacity of 18 million passengers, with a total building area of about 260,000 square meters. T2 was opened on July 12, 2014, is the main building plus the promenade of the front column of the domestic and international integrated terminal building, design annual passenger throughput of 18 million, with a total building area of about 260,000 square meters, 51 new seats, from top to bottom there are four floors, respectively, for the departure level, the arrival of the mezzanine, the apron level and the common ditch underground engine room level.

The T2 terminal building adopts the conceptual design program of France Paris Airport Engineering Company, innovatively designed by East China Architectural Design and Research Institute, the metal roof of the main building consists of 9 drums, gradually decreasing from the center to both sides, in the form of multi-curved surfaces. The gradient wavy double curved roof, metal roof using "large span, small curvature, multi-variable" structure, the first of its kind in China, is the largest single transportation project in Jiangsu.

Project Overview:

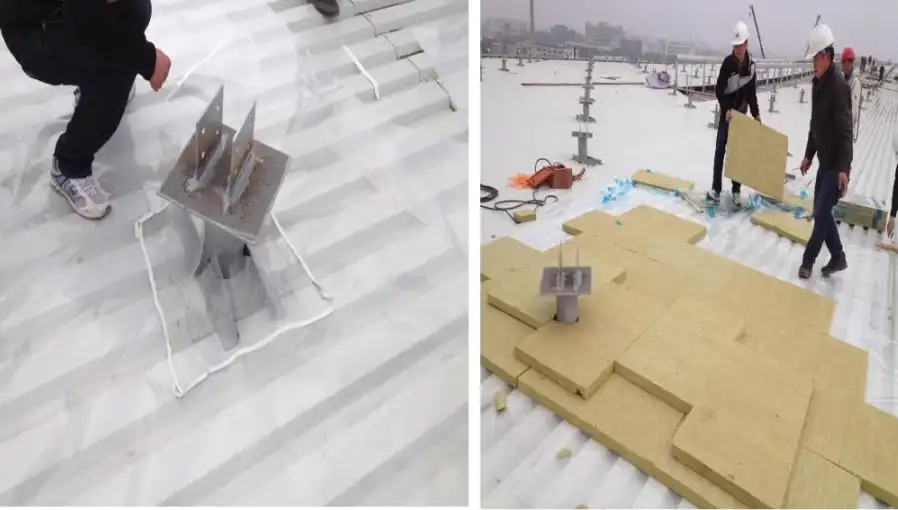

The roof of T2 terminal building of Nanjing Lukou International Airport is a double curved roof. The depth direction of the roof is a complex arc and the width direction is a continuous gradient wave shape, which has a complicated form and high construction difficulty. The total projected area of the terminal floor is 105,257 square meters, and the unfolded area is 107,552 square meters. Among them, the projected area of glass skylight is 6382 square meters, and the unfolded area is 6646 square meters. This project's roof waterproofing grade is 1 level. Roofing using two waterproofing: the upper waterproofing layer is 0.9mm thick aluminum magnesium vertical locking roof panels: the lower waterproofing layer is 1.5mm thick waterproofing roll-roofing material, the same color as the metal plate.

Roofing project consists of vertical locking aluminum alloy roofing system, flexible membrane waterproofing system, glass skylight system, 4mm thick S316 stainless steel gutter drainage system, lightning protection system, maintenance pull ring, gable end 30mm thick honeycomb aluminum panel wrapping system and other components.