Abstract: This article provides an in-depth exploration of C steel purlins, shedding light on their definition, invention, characteristics, advantages, and diverse applications. C steel purlins, essential components in construction and structural engineering, offer remarkable strength, versatility, and cost-effectiveness. Understanding their origins, unique features, and wide-ranging applications is crucial for optimizing their usage in various construction projects.

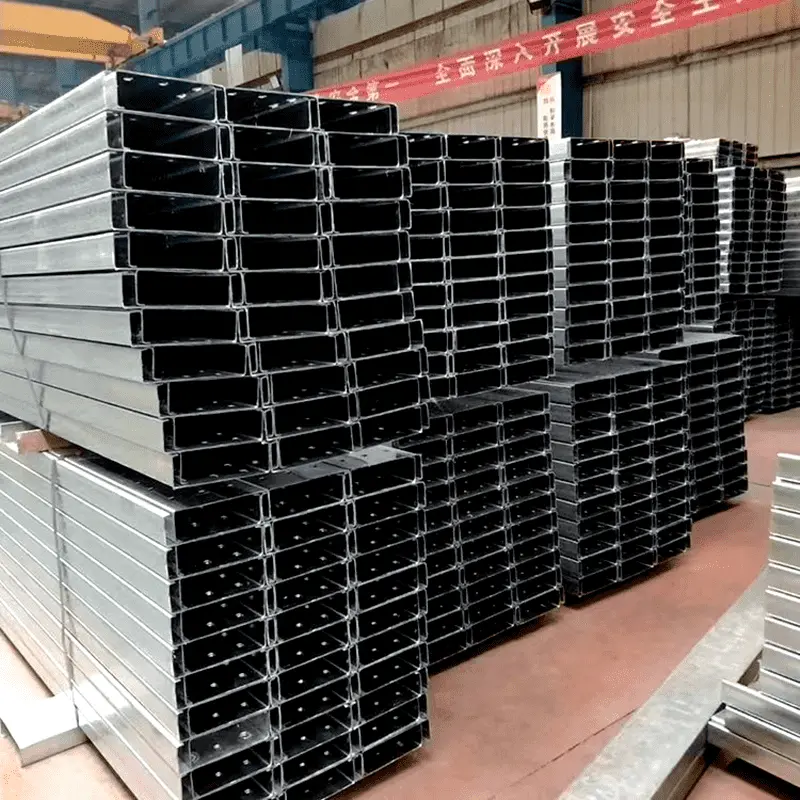

1. Introduction: C steel purlins, also known as C-channel purlins, represent a vital structural element extensively utilized in roofing and cladding systems, as well as in secondary framing applications. Their distinctive C-shaped cross-section enables efficient load distribution and structural support within building frameworks. This article delves into the historical development, defining features, advantages, and multifaceted applications of C steel purlins.

2. Invention and Evolution: The inception of C steel purlins dates back to the early 20th century, coinciding with advancements in steel manufacturing and building construction techniques. The development of C steel purlins was driven by the need for lightweight, durable, and cost-effective solutions to support roof and wall systems in industrial, commercial, and residential structures. Over time, engineering innovations have refined the design and manufacturing processes of C steel purlins, enhancing their performance and applicability across diverse construction projects.

3. Characteristics and Advantages: C steel purlins exhibit several distinctive characteristics and advantages that contribute to their widespread adoption in construction:

a. High Strength-to-Weight Ratio: C steel purlins are fabricated from high-strength steel alloys, enabling them to withstand substantial loads while maintaining a lightweight profile. This results in efficient material usage and reduced transportation costs.

b. Versatility in Design: The C-shaped profile of steel purlins allows for versatile design configurations, accommodating various roof slopes, spans, and architectural styles. They can be easily tailored to meet specific project requirements, facilitating efficient construction processes.

c. Ease of Installation: C steel purlins are prefabricated to precise dimensions, simplifying installation and minimizing onsite labor requirements. Their standardized profiles and connections enhance construction efficiency and reduce installation time, contributing to overall project cost savings.

d. Corrosion Resistance: Steel purlins are often coated with protective finishes such as galvanization or metallic coatings, enhancing their resistance to corrosion and extending their service life in diverse environmental conditions.

e. Cost-Effectiveness: C steel purlins offer a cost-effective solution for structural framing, providing a balance between performance, durability, and affordability. Their long-term durability and minimal maintenance requirements translate to enhanced lifecycle cost savings for building owners.

4. Applications: C steel purlins find wide-ranging applications in various construction projects, including:

a. Roofing Systems: C steel purlins serve as primary structural elements in roofing systems, supporting roof panels and facilitating efficient water drainage. Their versatility and load-bearing capacity make them suitable for use in both commercial and residential roofing applications.

b. Wall Cladding: Steel purlins are utilized in wall cladding systems to provide structural support for exterior cladding materials such as metal panels, siding, or curtain walls. Their ability to accommodate different cladding types enhances architectural design flexibility.

c. Secondary Framing: C steel purlins are commonly employed as secondary framing members in steel building systems, complementing primary structural elements such as columns and rafters. They contribute to the overall stability and integrity of the structure while minimizing material usage and construction costs.

In conclusion, C steel purlins represent a cornerstone of modern construction, offering a versatile, durable, and cost-effective solution for structural framing applications. Their evolution, unique characteristics, and diverse applications underscore their significance in the built environment, serving as indispensable components in a wide array of construction projects. As the construction industry continues to evolve, C steel purlins are poised to remain indispensable elements in the pursuit of efficient, sustainable, and resilient building solutions.