Abstract: This paper presents a comprehensive analysis of H shape steel beams, elucidating their origins, utility, advantages, and manufacturing techniques. H shape steel beams, known for their distinctive cross-sectional shape resembling the letter "H", play a pivotal role in various construction and structural engineering projects. Understanding the evolution, applications, benefits, and production methods of H shape steel beams is crucial for optimizing their utilization in diverse structural applications.

1. Introduction: H shape steel beams, also referred to as H-beams or H-sections, constitute an essential component in modern construction and structural engineering. Their unique cross-sectional configuration, characterized by a wide flange and narrow depth, imparts superior load-bearing capabilities and structural stability. This paper delves into the historical development, functional significance, advantages, and manufacturing processes of H shape steel beams.

2. Origin of H Shape Steel Beams: The concept of H shape steel beams originated in the early 20th century, evolving from the I-beam design to accommodate larger loads and span greater distances. The development of H shape steel beams is attributed to advancements in metallurgical engineering and structural design, which enabled the optimization of beam profiles for enhanced strength and efficiency.

3. Utility and Advantages: H shape steel beams find extensive application across a spectrum of structural frameworks, ranging from buildings and bridges to industrial facilities and infrastructure projects. The key utility and advantages of H shape steel beams include:

a. Load-Bearing Capacity: The wide flange design of H shape steel beams distributes loads more effectively, enabling them to support heavier loads over longer spans compared to traditional beams.

b. Structural Stability: The symmetrical H shape design provides inherent stability against bending, torsion, and shear forces, enhancing structural integrity and safety.

c. Versatility: H shape steel beams offer versatility in structural configurations, facilitating innovative design solutions and architectural flexibility.

d. Cost-Efficiency: Despite their robustness, H shape steel beams offer a favorable strength-to-weight ratio, resulting in reduced material usage and construction costs.

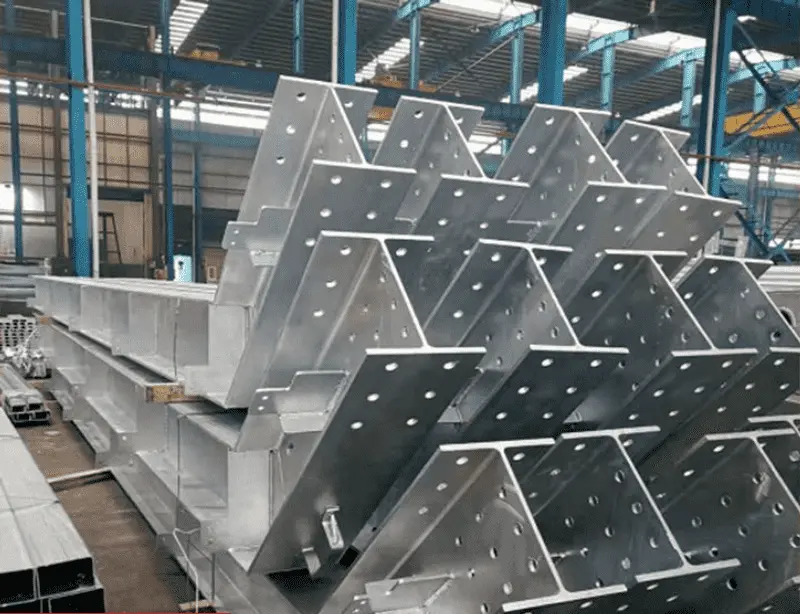

4. Manufacturing Methods: The manufacturing process of H shape steel beams involves several sequential steps, encompassing material selection, shaping, and finishing. The primary manufacturing techniques include:

a. Raw Material Selection: H shape steel beams are typically fabricated from low-carbon steel or alloy steel, chosen based on desired mechanical properties and application requirements.

b. Hot Rolling: The fabrication process commences with hot rolling, wherein steel billets or blooms are heated to high temperatures and passed through a series of rollers to form the H shape profile.

c. Cooling and Straightening: The hot-rolled H shape sections undergo controlled cooling to optimize metallurgical properties and straightening to ensure dimensional accuracy.

d. Surface Treatment: Surface treatment methods such as shot blasting, painting, or galvanization may be employed to enhance corrosion resistance and aesthetics, depending on the intended application.

6.Industrial Facilities: H shape steel beams play a crucial role in the construction of industrial facilities, including warehouses, manufacturing plants, and distribution centers. Their robustness and load-bearing capacity make them suitable for supporting heavy equipment, machinery, and storage systems, while their versatility enables the creation of large, column-free spaces to accommodate production processes.

7. Conclusion: In conclusion, H shape steel beams represent a cornerstone of modern construction and structural engineering, offering unparalleled strength, stability, and versatility. Understanding their origins, utility, advantages, and manufacturing processes is essential for harnessing their full potential in diverse structural applications. Continued advancements in manufacturing technologies promise to further enhance the performance and sustainability of H shape steel beams, cementing their significance in the built environment for generations to come.