Description du produit

Heavy Pollution Industrial Used Excellent Anti-corrosion Long Lifetime FRP Polyester Roof Sheet

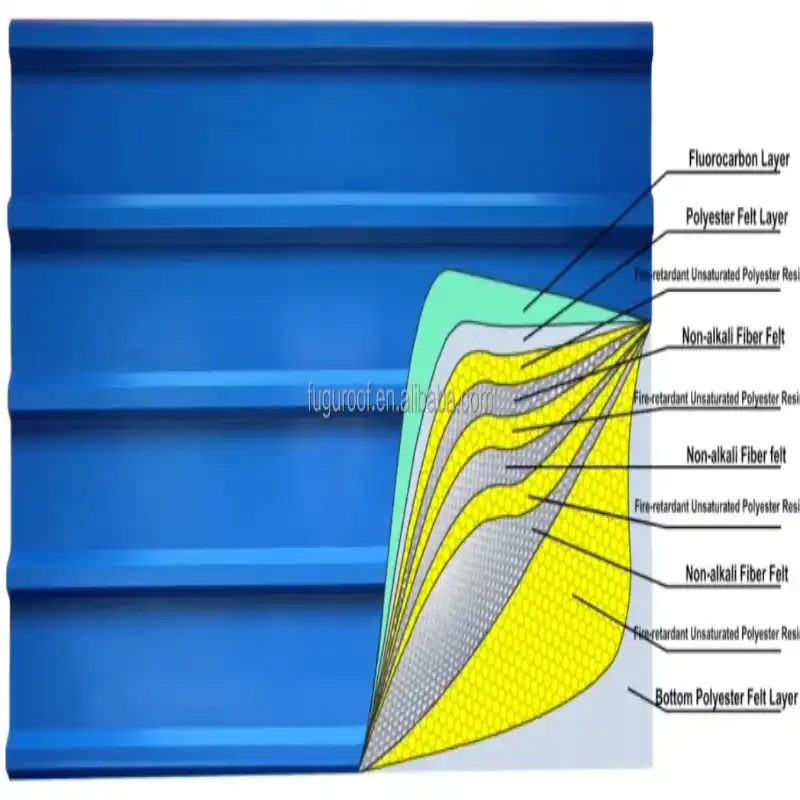

FUGU Anti-Corrosion Polyester Sheets adopt unsaturated polyester resin as main raw material and non-alkali fiberglass chopped stitch felt as main reinforced material, plus with weather-resistance polyester felt and fluorocarbon coating. It is the high density and strength sheets that produced under high temperature & pressure of 8000KG tensile force with the current most advanced composite pultrusion technology.And also have solved the problems of FRP corrugated sheets for uneven thickness, rough, low weather-ability, film easy aging off, flammable,easy chalking and cracking, and no hydrofluoric resistance, etc.

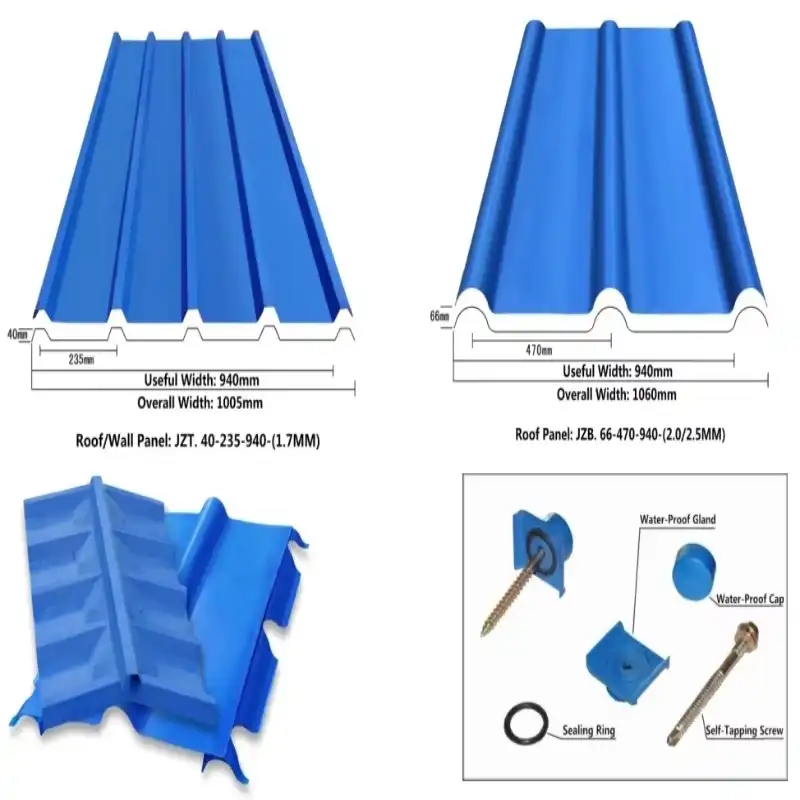

| Model | Over width | Useful width | Wave Height | Thickness | Longueur |

| JZT.40-235-940 | 1005mm | 940mm | 40mm | 1.7-3.0mm | Customized(<5700mm for 20’Container <11700mm for 40’ container) |

| JZB.66-470-940 | 1060mm | 940mm | 66mm | 1.7-3.0mm | |

| Purlin Distance | 600-2000mm | 600-2000mm | 600-2000mm | 600-2000mm |

Product Fonctionnalité

Stable Geometry Performance, Excellent High And Low Temperature Resistance: FuGu Anti-Corrosion Polyester Sheet are soiled and shaped under the average production temperature of 192℃. After testing, the heat distortion temperature is higher than 250℃ and the thermal expansion coefficient is 1.92X10-5/℃-1. There is no crack, hollowing, bubble and peeling off after 30 times’ freezing cycle testing. Therefore there is no droop, swell and deformation during use.

Doubly protected by fluorocarbon coating and polyester felt, ensure long lifetime and still keep the

stability even chronically exposure in the environments of UV, hot, cold, damp and corrosive.( △E<5 via CN10000 hours’ weather resistance test by CNAC, accordance with Nation Technical Standard. Note: 10000 hours in lab is equal to 28 years in nature environment.)

Excellent Corrosion Resistance: The materials of FuGu Anti-Corrosion Polyester Sheet itself have the natural anti-corrosion characteristics. There is no obvious change after soaking 120 hours in the solutions of 15% hydrochloric acid, 20% sulfuric acid, 40% hydrofluoric acid, 15% silicofluoric acid, 20% phosphate, 20% nitrate, 5% sodium hydroxide and ammonia. Strong Wind Resistance: JULI Anti-Corrosion Polyester Sheets themselves are tough and compact which can withstand 2000pa wind pressure (equal to wind grade 8~10)

Excellent Anti-Hail Performance: There is no broken and damage within 50mm hails for JULI Anti-Corrosion Polyester Sheets have adopted non-alkali fiberglass chopped stitch felt as reinforced material with high impact-resistance. Test with 1KG steel ball free falling from 3M height, no any breaking.

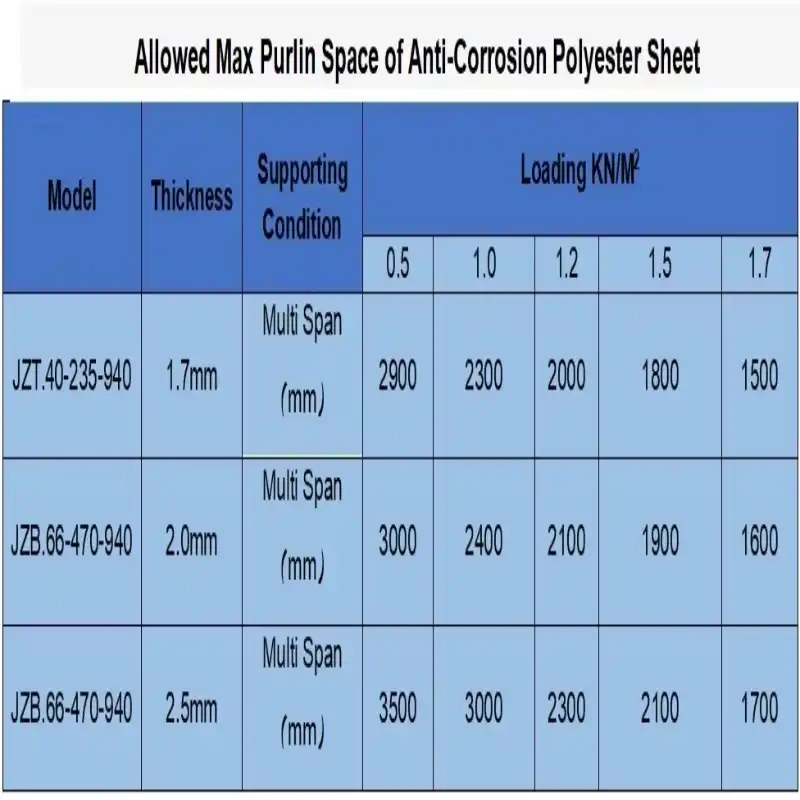

Excellent Load-Carrying Performance: Adopts the advanced composite pultrusion technology, with excellent mechanical strength and physical properties.

Color Shows

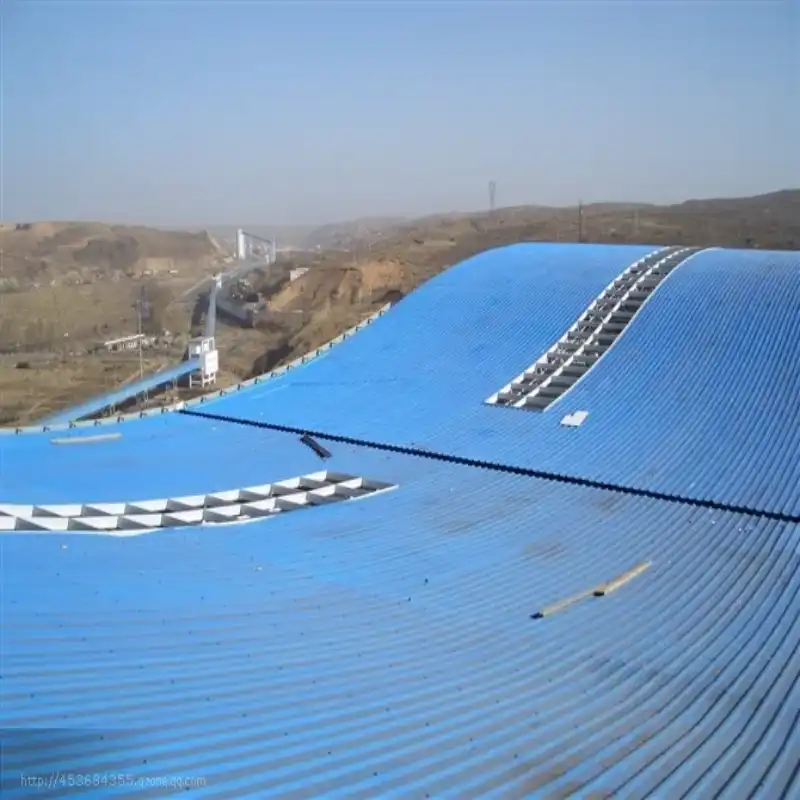

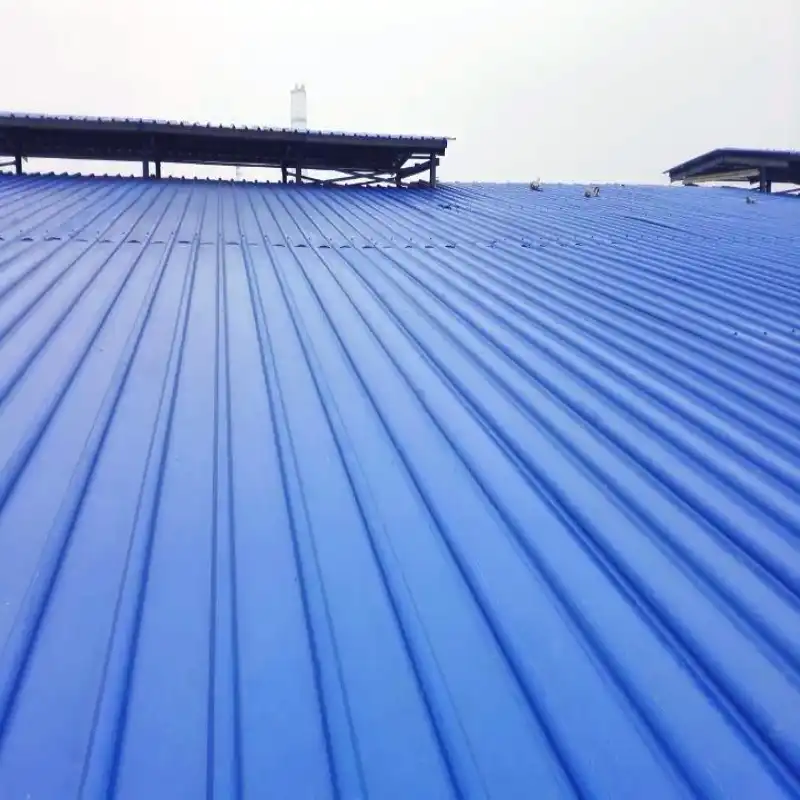

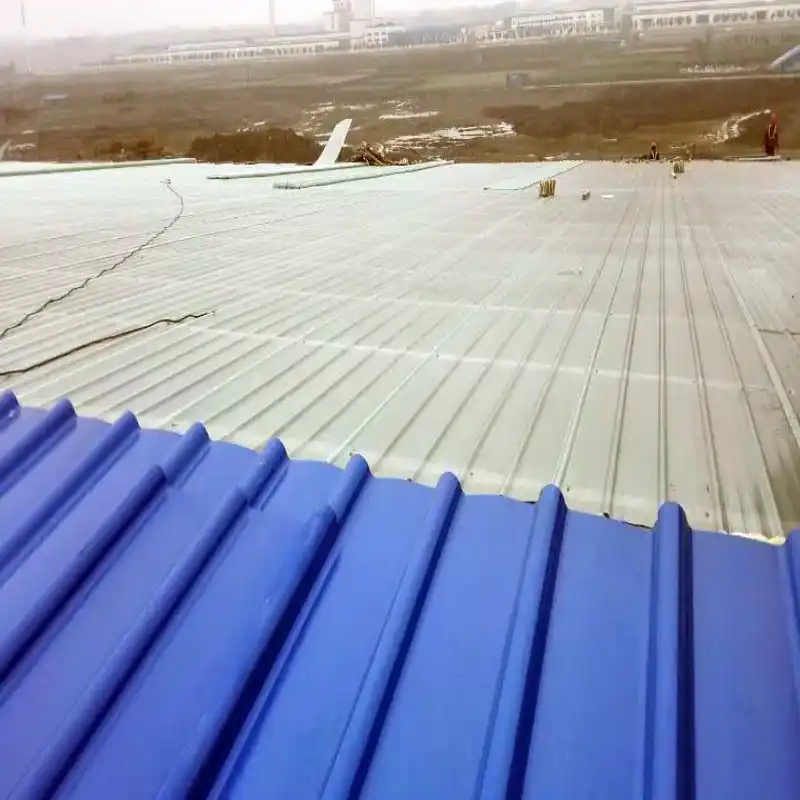

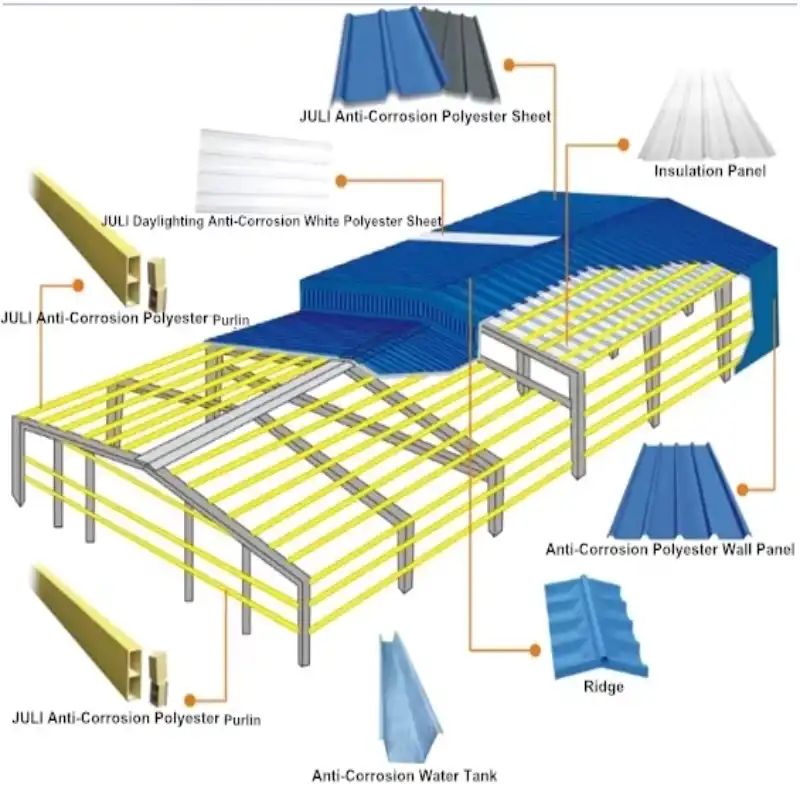

Workingshop

FUGU Building Material Group, specializing in producing and marketing green environment-friendly products for construction and municipal engineering projects, loaded at Hefei City, which is the capital of Anhui province, with production sites in Anhui, Jiangsu, Zhejiang, Hebei, Shandong and Fujian Provinces. PE Resin Plastic Artificial Thatch Simulated Straw for Roof Tiles in Tourist Attractions

Installation

Installation Of FuGu Anti-Corrosion Polyester Sheet:

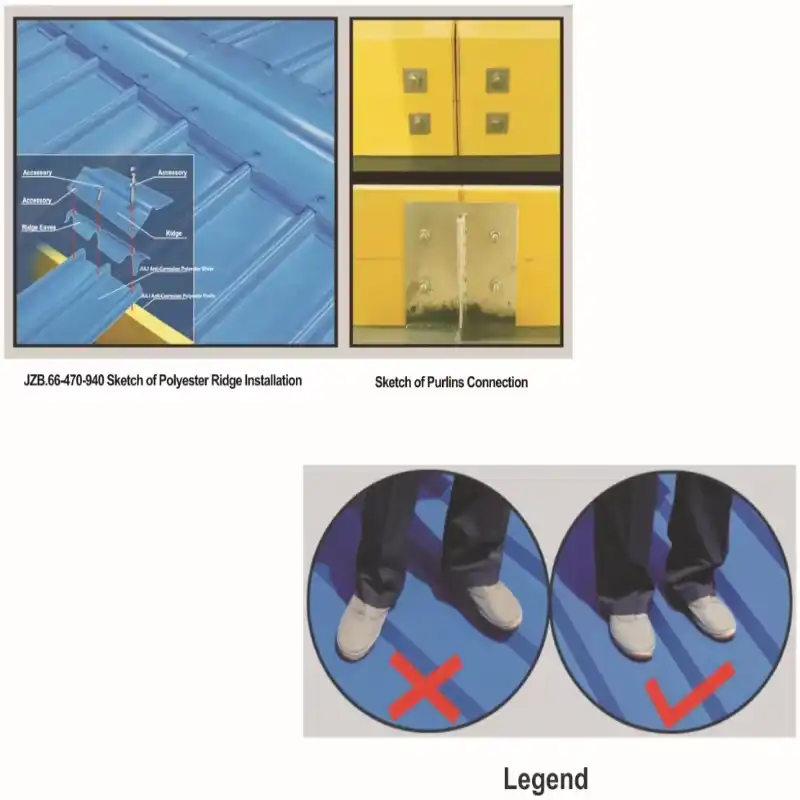

1. Model: JZT.40-235-940 (roof and wall sheets) and JZB.66-470-940 roof sheets.

2. Above models are suitable for the roof span 1:5~1:20.

3. Can be directly covered on flat thermal insulation material.

4. Overlap:

* Width overlap (transverse overlap) request: JZT and JZB series’ wall and roof sheets, all overlap a wave.

* Length overlap (longitudinal overlap) request: Over purlins’ length is not less than150mm.

* Over eaves’ length: <250mm

5. Fixing:

* Use special anti-corrosion and waterproof accessories which produced by our factory, and fixed by self-tapping screws.

* Each purlin and roof sheet should evenly fix with two sets accessories. The accessories should be fixed on wave crest and flat surface only available for some special conditions.

* It shouldn’t be too tight when install self-tapping screws with the measurement for non-deformation of roof sheets, or else, might influence flatness.

* Each wave crest of roof sheets must be fixed on purlins at the longitudinal edges and each roof sheet should be add fixing accessories at windy areas.Power Station Used Hydrofluoric Acid Resistance 45 Years Lifetime FRP Polyester Roof Sheet

* Don’t fix the ridges separately on the underneath roof sheets by rivet, must fix ridges and roof sheets together on the

underneath purlins by self-tapping screws.

6. Installation:

* In order to ensure people safety during installation, must use ladder and other qualified safety facilities and fasten safety belt.

* Don’t step on the middle of two purlins but must on the purlins. Don’t step on wave crest of roof sheets, especially JZT series sheets, but must be on wave trough. Please checking the photos as above.

* When install ridge roof, the top of sides’ roof sheets should butt together and align. Then installed simultaneously with

ridges.

* When install under the temperature of -5℃, take effective slip-resistant measures, and fasten safety belt.

* Please be installed by professional qualified installation team to ensure good installation quality.

7. Drilling

* Drilled by electric drill.

* When drill, ensure roof sheets have placed well on purlins.

* Directly drilled by self-tapping screws and appropriately fasten but ensure roof sheets are non-deformation.