Indonesia Belden Power Station

Project Overview:

The Paiton Power Station is located in Paiton District, Probolinggo City, East Java Province, Indonesia, about 150 kilometres from Surabaya, the second largest city in Indonesia. With a total installed capacity of 4,725MW and a total of 8 units, Paiton Power Station is the world's 10th largest coal-fired power station complex and one of the two largest coal-fired power station complexes in Indonesia (the other one is the Suralaya coal-fired power station complex located in Banten Province). The project has a total of 8 units.

Indonesia Baitong 1x660MW power station is a large coal-fired thermal power plant, the boiler is designed and manufactured by Harbin Boiler Co., Ltd. with sub-critical parameters, control cycle steam drum boiler; primary intermediate reheat, balanced ventilation, all steel frame suspension structure; four-corner cut-circle combustion; semi-open-air arrangement, solid slag discharge, open-air arrangement, all-steel structure. The turbine is subcritical, primary intermediate reheat, three cylinders and four exhausts, single shaft, gas condensing (double back pressure). The cooling method of the generator is water, hydrogen and hydrogen, and the excitation adopts machine-end self-parallel excitation magnetic system. The project is designed by Central South Power Design Institute, constructed by Beijing Electric Power Construction Company, and supervised by Indonesia JMK Supervision Company and US MSHE Supervision Company and Harbin Power Station Engineering Company Limited for quality supervision and inspection.

Translated with DeepL.com (free version)

Engineering Geology:

The proposed site is located in the seaside mudflat, and the original landform is a gentle beach in front of the mountain, which is a pile-type shallow.

The original ground elevation is -2.36~3.10 mountains, slightly inclined to the sea. The site was artificially filled during the pre-construction of the power plant, and the site has basically become a gently open and flat land, with the current ground elevation ranging from 0.76 to 4.54 m (the general elevation is about 2.50 m). The site is surrounded by hills and low mountains to the south and the sea to the north.

Building Part:

(1) The main plant, centralised control building adopts steel structure, and the enclosure structure and steam engine house surface adopts self-waterproof insulated metal plate.

(2)Steel columns and beams are used in the deaerated coal bunker, the floors (roofs) of the centralised control building, the running floors of the steam engine room and the heater platform, and the poured-in-place concrete slabs are used as the base moulds for the pressurised steel plates.

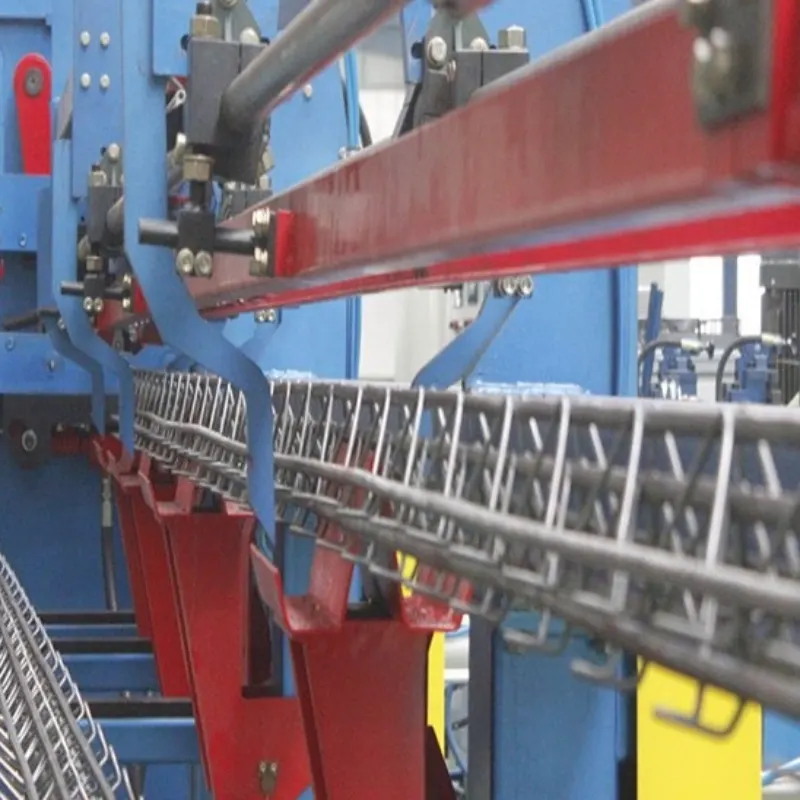

(3) The coal conveying trestle adopts steel pillars and steel trusses, and the bottom plate of the coal conveying trestle adopts reinforced concrete structure with metal compression steel plate as the bottom mould, while the enclosure structure and roofing adopts self-waterproof metal heat preservation board.

(4) the roof of the coal bunker and other ancillary building roof waterproofing using modified bitumen membrane waterproofing.

All underground structures with waterproofing requirements adopt waterproof concrete.