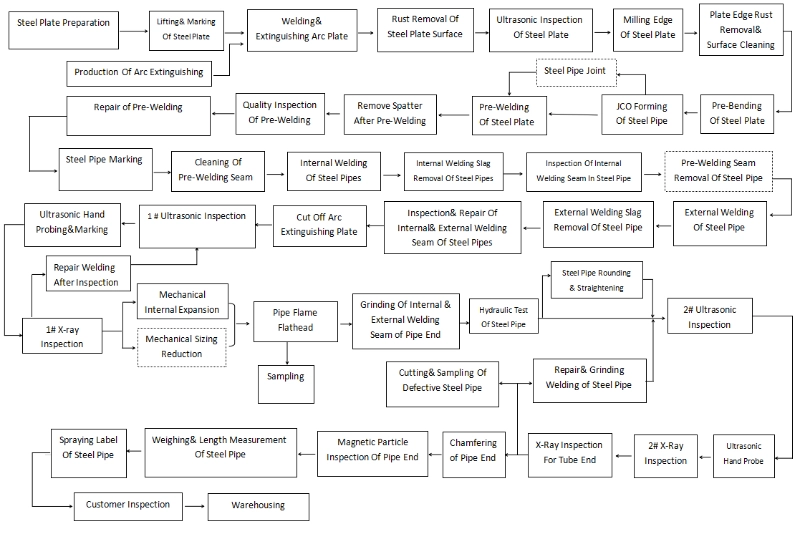

The JCOE pipe production lines of Honglu Steel Structure Group are currently the most advanced sixth generation pipeline production line in China, the production efficiency has increased by 30% compared to the previous generation, advanced equipment and high automation.

Product Specification:

| Product Name | Production Range | ||

| Diameter | Wall Thickness | Length | |

| ERW Pipe | Ø400-1700mm | 10-50mm | Single length between 6-12.4 meters |

| Rolled Welded Pipe | Ø600-3500mm | 10-50mm | Single length≤3meters |

| Conical Welded Pipe | Conical welded pipe is large and small head pipe, and the small head diameter should be >500mm, diameter reduction ≤ 400mm | 10-35mm | Single length≤2meters |

| ERW High-Frequency Welded Pipe | Pipe Diameter 76mm-245mm | 2mm-8mm | Single length: Customized according to customer needs |

| Pipe Production Lines | JJCOE Pipe Production Line, Rolling-Pipe Production Line, Conical Welded Pipe Production Line, ERW High-Frequency Welded Pipe Production Line | ||

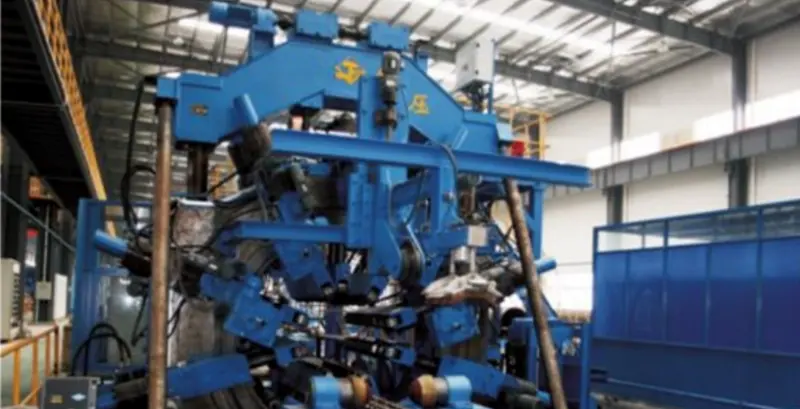

JCOE Pipe Production Machine

Edge Milling Machine

The milling tool composed of four front and rear cutting discs, fully guarantees the milling quality of steel plate and greatly improves the quality of weld-seam.

Pre-Bending Machine

The unilateral pre-plate pressing force is 600 tons, and 500mm thick steel plate can be fully pre-bent to ensure the arc accuracy at the weld-seam of steel pipe.

CNC Bending Machine

The latest generation CNC bending machine with a capacity of 3600 tons adopts the CNC system of DeLem Company in Netherlands, which improves the host working efficiency by 30% compared to the previous generation.

Tack Welding Machine

The formed steel pipe achieves automatic seam-welding on seam pre-welding machine, thereby improving the joint efficiency and greatly improving the weld-seam quality of the next process (internal and external welding).

External Welding Machine

Having two internationally renowned "Lincoln" welding power sources as main internal and external welding wires.

Internal Welding Machine

Precision Machine

The nominal force is 2000 tons, which fully guarantees the elliptical precision of steel pipe.

Straightening Machine

The nominal force is 600 tons, which fully ensures the straightness of steel pipe.

Roller Bending Machine

ERW Pipe Production Line

Product Range:

Pipe Diameter: 76mm~245mm,

Wall Thickness:2mm~8mm

Length: According to customer requirements