Nianchu River Steel Pipe Arch Bridge Of La Ri Railway

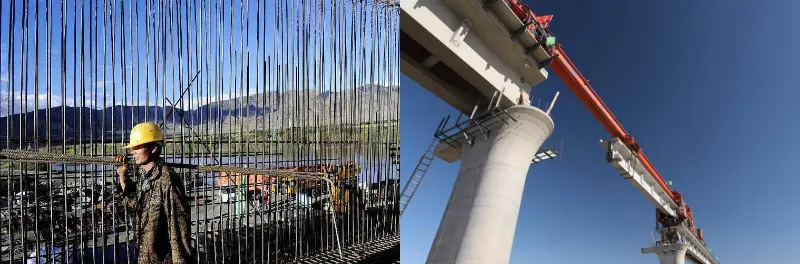

Nianchu River Steel Pipe Arch Bridge of Lazhi Railway has a total length of 1106.52 meters, with the main span (148 meters) and continuous girders on both sides (60 meters on each side) having a total length of 268 meters. It is a composite structure composed of large-span prestressed reinforced concrete continuous girders and concrete-filled steel pipe arches. It is a new structural form of railway bridge in China. The construction technology is difficult and the monitoring accuracy is required to be high. Among them, the installation measurement of the main span continuous girder and steel pipe arch rib is the key and difficult point of the railway engineering construction measurement.

Construction Process Introduction:

Nianchu River Bridge is a mega bridge with novel structural form, located on the Lhasa-Rikaze railway. The bridge is an organic combination of V-type continuous rigid structure and concrete-filled steel pipe arch, giving full play to the advantages of V-type rigid structure and arch bridge in structural behaviour, which not only meets the requirements of safety and comfort of train travelling, but also coordinates with the surrounding natural landscape.

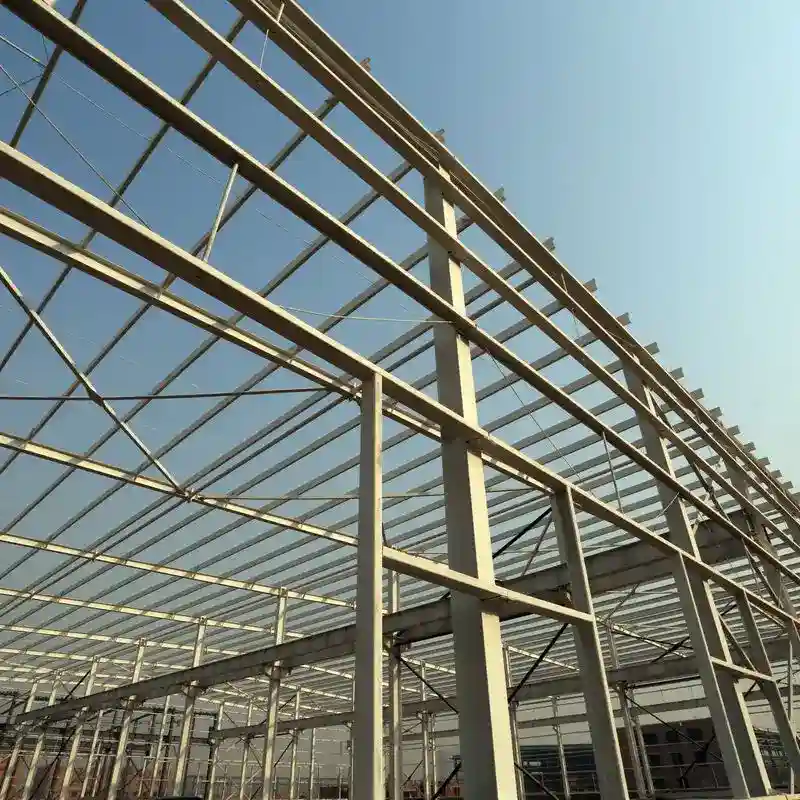

The main bridge is constructed according to the sequence of "beam first and arch later". Pile foundation construction is mainly rotary digging, and impact drilling is also used; 18#19# bearing platform pit is protected by reinforced concrete cofferdam, and cooling pipes are preset on the bearing platform to cool down the concrete; V-type inclined leg support is made of bowl-buttoned small steel pipes and reinforced by fastening small steel pipes, diagonal braces and scissor braces; the section of pre-stressed continuous girder across the river channel adopts the method of casting support by steel pipe piles, and the other sections adopt bowl-buttoned small steel pipes casting support method The other sections were supported by bowl-button type small steel pipes. During construction, it also cooperates with the third-party monitoring unit to control the linearity of the girder; the steel pipe arch is factory-produced and assembled into components of about 10 metres according to the design coordinates and transported to the site, and the trellis frame and steel arch components are symmetrically lifted segment by segment by using crawler cranes; micro-expansion concrete for the arch ring adopts multiple pumps to follow the principle of symmetry and uniformity, and is pumped and jacked up from the foot of the arch to form a steel pipe concrete arch, and it can be installed after assisting and equalising the pressure. Boom and symmetrical tensioning in batches; finally remove the tyre racks and steel pipe pile supports, construct the second stage of the constant load and bridge deck system, and adjust the tension of the boom again.