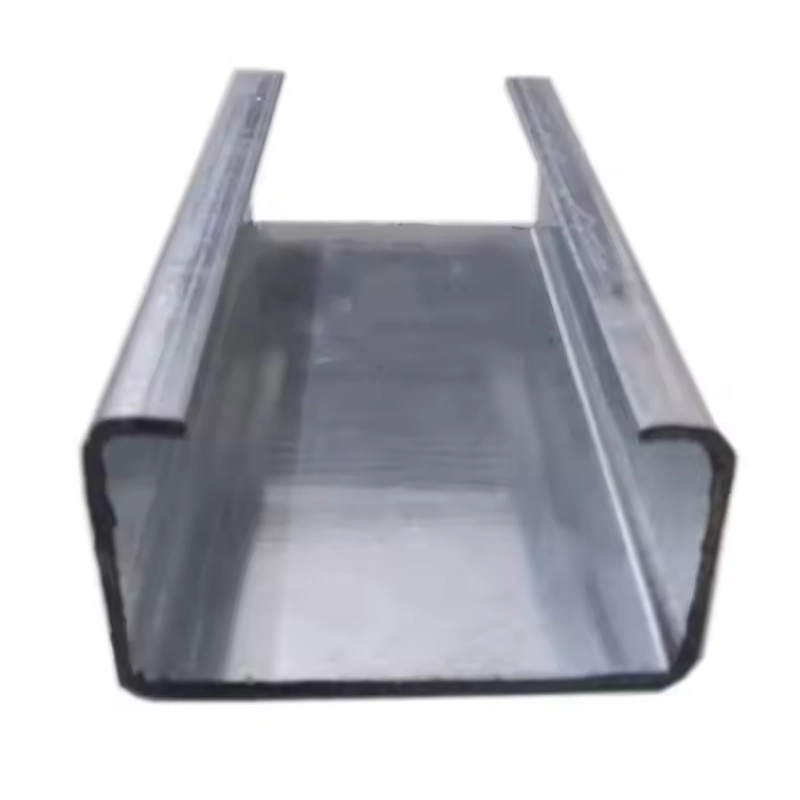

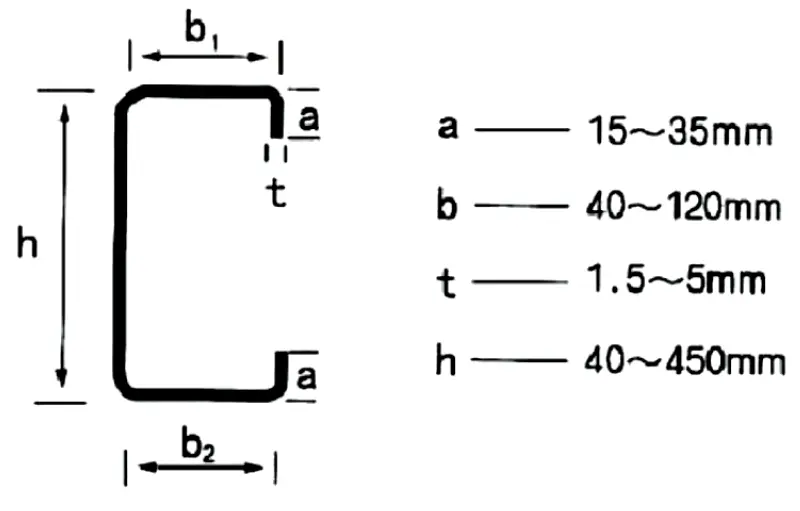

What is C-shaped steel?

C-shaped steel, also known as channel steel, is a common type of steel that is named because of the cross-sectional shape is "C" . The cross-section of C-shaped steel is divided into two parts: Channel Web and Channel Wing. The Channel Web is the part connecting the Channel Wings, which are two relatively symmetrical parallel wing plates.

C-shaped steel is with high strength and rigidity, very suitable for structures that withstand large loads and bending torsion.

What are the specifications of C-shaped steel?

C-shaped steel purlins are mainly divided into five specifications based on different height: 80, 100, 120, 140, and 160. The use scope may vary depending on the different specifications, and reasonable selection will be made according to construction design requirements.

In addition, the length of C-shaped steel is generally determined based on the engineering construction design, but considering convenient transportation and installation conditions, the total length generally does not exceed 12 meters.

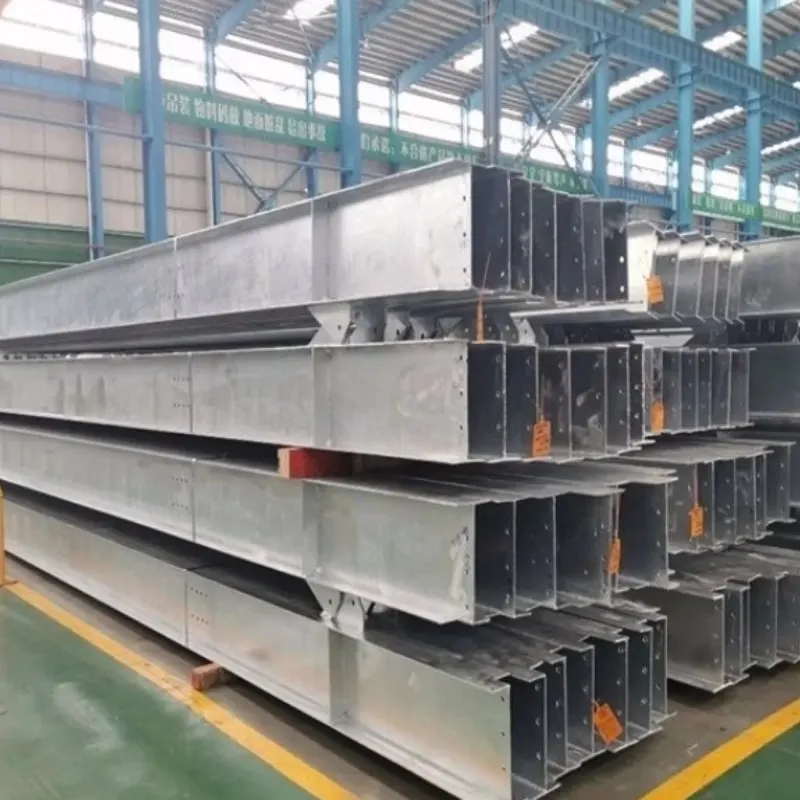

As an extension of the industrial chain of Honglu steel structure, steel purlin production lines are distributed in five major production bases, including Hefei, Anhui, Guoyang, Bozhou, Nanchuan, Chongqing, Tuanfeng, Hubei, and Ruyang, Henan.

At present, we have 60 advanced intelligent servo automatic cutting C/Z steel production lines, which can be used for punching production. The width and height can be adjusted freely, and can meet customer customization requirements as needed. The monthly output is over 50000 tons.

C-shaped steel, as a common steel with unique shapes and properties, has the characteristics of high strength, lightweight, convenient construction, economic practicality, environmental protection, energy conservation, and strong adaptability. It is widely used in various structural engineering, playing an important role in construction, bridges, mechanical manufacturing, and other fields. With the development of industry and construction, the application prospects of C-shaped steel in the future will be more broader.

Product Description

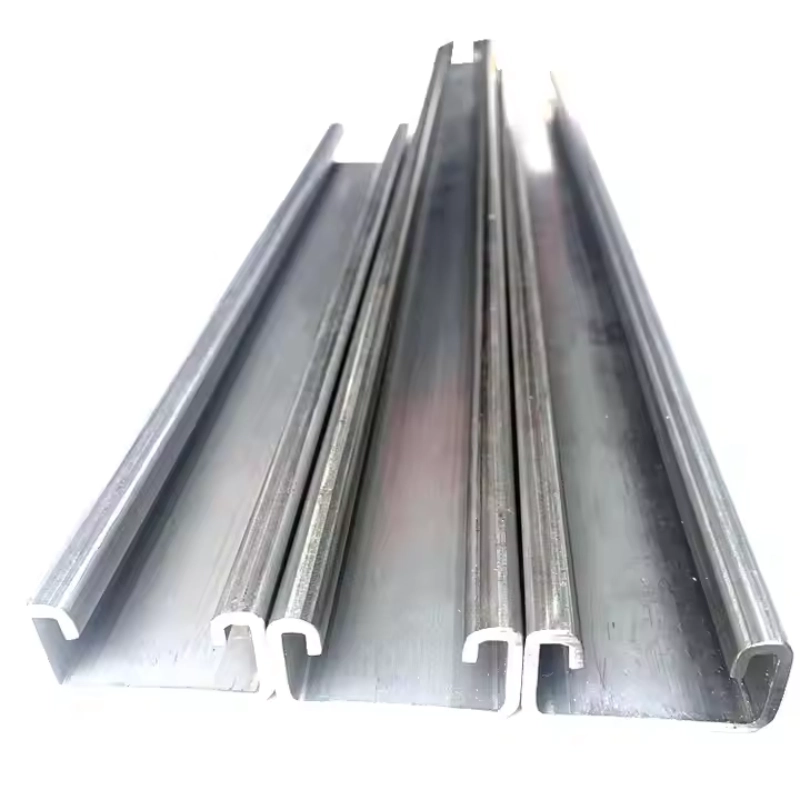

| Size | 1.Web Width (H): 37mm-88mm 2.Flange Width (B): 50-400mm 3. Web Thickness (t1): 4.5-8mm |

| Standard | JIS G3101 EN10025 ASTM A36 ASTM A572 ASTM A992 |

| Grade | Q235B Q345B Q420C Q460C SS400 SS540 S235 S275 S355 A36 A572 G50 G60 |

| Length | 12m 6m or customized |

| Technique | Hot rolled |

| MOQ | 1 ton |

| Packing | In bundle fasten by steel strip |

| inspection | SGS BV INTERTEK |

| Application | Construction structure |

Application:

1.Seismic Support

2.PV Support

3.Lightweight building components such as roof trusses and brackets.

4.Columns, beams, and arms in mechanical light industry manufacturing

Products features:

1.high pressure resistance,

2.long support time,

3.easy installation

4.deformation resistance

Packing & Shipping

| NO. | Description | Pictures Showed |

| 1 | All of the steel columns&beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shippment. |  |

| 2 | To make the loading and unloading more effieciently and saving the delivery cost 40'OT is prefered to loading the steel frames |  |

| 3 | All the wall&roof panels will be filmed by two sides and fixed stably in the 40'HQ container. |  |

| 4 | All the windows and doors will be protected by the bubble rapping papers and fixed stablely in the container. |  |

All the solutions for your:

Industrial steel buildings:

steel structure buildings,steel hangar kits, steel hall, steel structure storage shed, steel structure warehouse, steel structure workshop, steel construction building,processing plants

Commercial steel buildings:

Logistics Warehouse, apartment building, office building, steel hotel building, steel structure mezzanine floor, steel structure shops, aircraft hangars, steel villa frame,platform, indoor horse arena ,churches,shopping malls,water tower,structural frame,

Agriculture steel buildings:

Hay shed, machinery shed, stands, poultry houses,poultry farm building,chicken farm buildings,chicken house,broiler house,cow barn ,cow shed, dairy farm building, pig building house, goat building house, calf barn etc

You can trust us:

- Design according to customer's requirements.

- Manufacture under complete quality control system-ISO9001

- Easy to assemble and dismantle.

- .Eco-friendly material:can be used for several times and can be recycled.

- Short construction period, long using time.

- Permanent and temporary resistance, labor camp, office workshop, warehouse and etc.

- Reasonable packing ensures the quality and convenience to transport and install

- Color steel sandwich panel has a good fire proof and heat insulation performance for the characteristic ofthe color steel sheet and polystyrene material