H-beam is a new type of economical and efficient profile with a more optimized cross-sectional area distribution and a more reasonable strength to weight ratio. It is named after its cross-sectional area is the same as the English letter "H".

Due to the fact that all parts of H-beam are arranged at right angles, H-beam has advantages such as strong bending resistance, simple construction, cost savings, and light structural weight in all directions, and has been widely used.

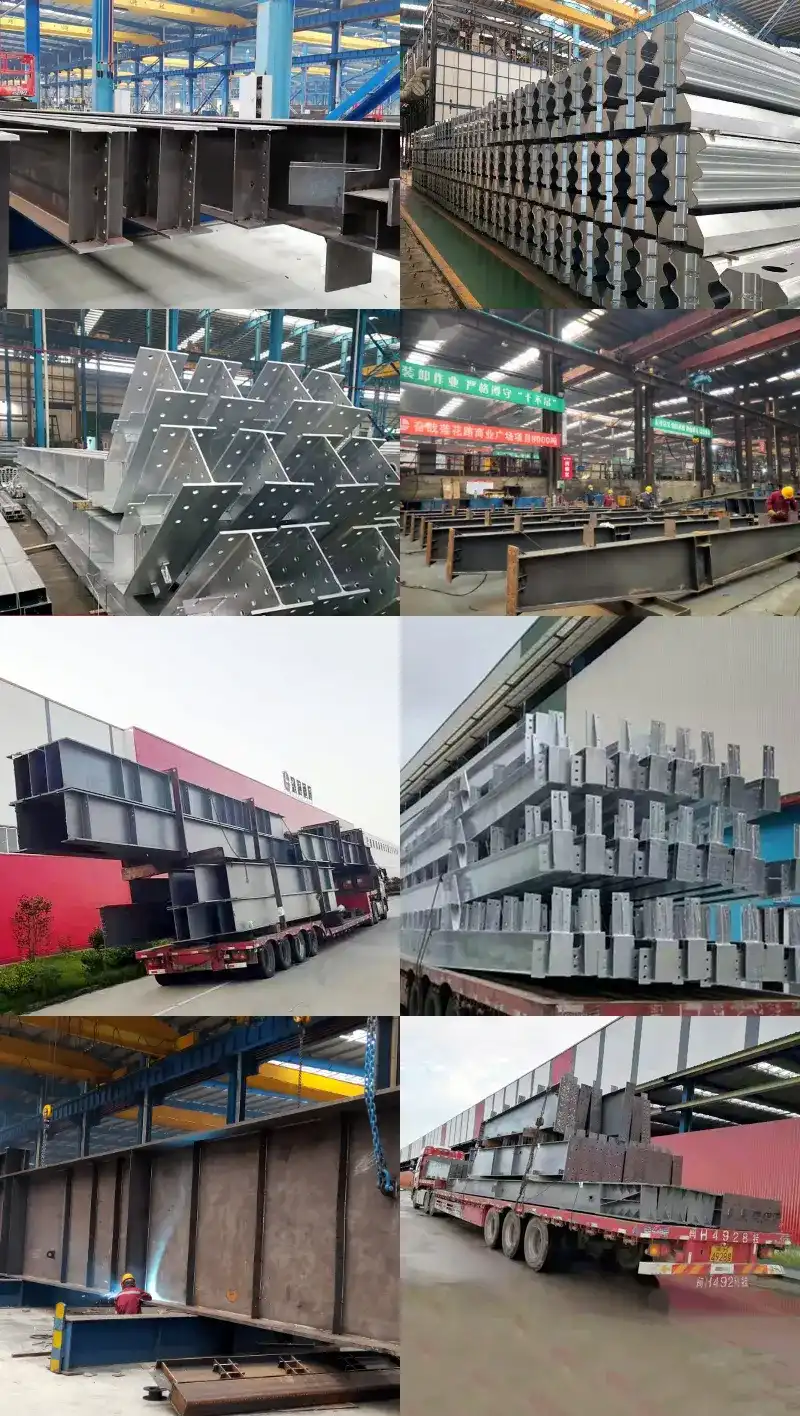

Product Classification: H beams are divided into two types: Hot-rolled H-beams and Welded H-beams (H).

Hot-rolled H-beams are further divided into three types: Wide Flange H-beams (HW), Medium Flange H-beams (HM), and Narrow flange H-beams (HN).

HW is the height and flange width of H-shaped steel that are basically equal. Mainly used for steel core columns in reinforced concrete frame structures, also known as rigid steel columns; Mainly used for columns in steel structures.

HM is an H-beam with a height to flange width ratio of approximately 1.33 to 1.75. Mainly used as steel frame columns in steel structures and as frame beams in frame structures under dynamic loads; For example: device platform.

HN refers to the ratio of H-shaped steel height to flange width greater than or equal to 2, mainly used for beams; The use of I-shaped steel is equivalent to that of HN shaped steel.

Product Material: The main materials of H-shaped steel include Q235B, SM490, SS400, Q345, Q345B, etc.

Introduction to H-shaped steel structure:

I-shaped steel has an economical and reasonable cross-sectional shape, good mechanical properties, and uniform extension at various points on the section during rolling with low internal stress. Compared with ordinary I-shaped steel, it has the advantages of large cross-sectional modulus, light weight, and metal saving, which can reduce the weight of building structures by 30-40%; Due to the parallel inner and outer sides of its legs and the right angle of its legs, it can be assembled into components, saving up to 25% of the welding and riveting workload. Commonly used in large buildings that require high load-bearing capacity and good cross-sectional stability (such as factories, high-rise buildings, etc.), as well as bridges, ships, lifting and transportation machinery, equipment foundations, brackets, foundation piles, etc.

Comparison between H-beam and I-beam:

H-shaped steel is an economical section steel with better mechanical properties developed from the optimization of I-shaped steel, especially named after the same section as the English letter "H". Its characteristics are as follows:

Wide flange and high lateral stiffness. Strong bending resistance, approximately 5% -10% higher than I-beam.

The two surfaces of the flange are parallel to each other, making it easy to connect, process, and install.

Compared with welded I-beams, it has low cost, high accuracy, low residual stress, and does not require expensive welding materials and weld seam testing, saving about 30% of the steel structure production cost.

Under the same cross-sectional load, the weight of hot-rolled H-steel structures is reduced by 15% -20% compared to traditional steel structures.

Compared with concrete structures, hot-rolled H-steel structures can increase the usable area by 6%, while reducing the self weight of the structure by 20-30%, reducing the design internal force of the structure.

H-shaped steel can be processed into T-shaped steel, and honeycomb beams can be combined to form various cross-sectional forms, greatly meeting the needs of engineering design and production.