In recent years, with the special manufacturing process requirements for key components and mechanical foundations of intelligent steel structures, automotive industry, engineering machinery, machine tools, large petrochemical plants, ships, and marine equipment, there has been a large demand for high-quality welding materials. In order to meet market demand and improve core competitiveness, Honglu has introduced advanced production processes and equipment at the first-class level in China, achieving intelligent production throughout the entire process and automated monitoring. By leveraging our technological leadership advantages to expand the scale of robot automated welding material production and welding equipment, achieving a leap in product quality and quantity improvement, and incorporating this into the Group's important strategy.

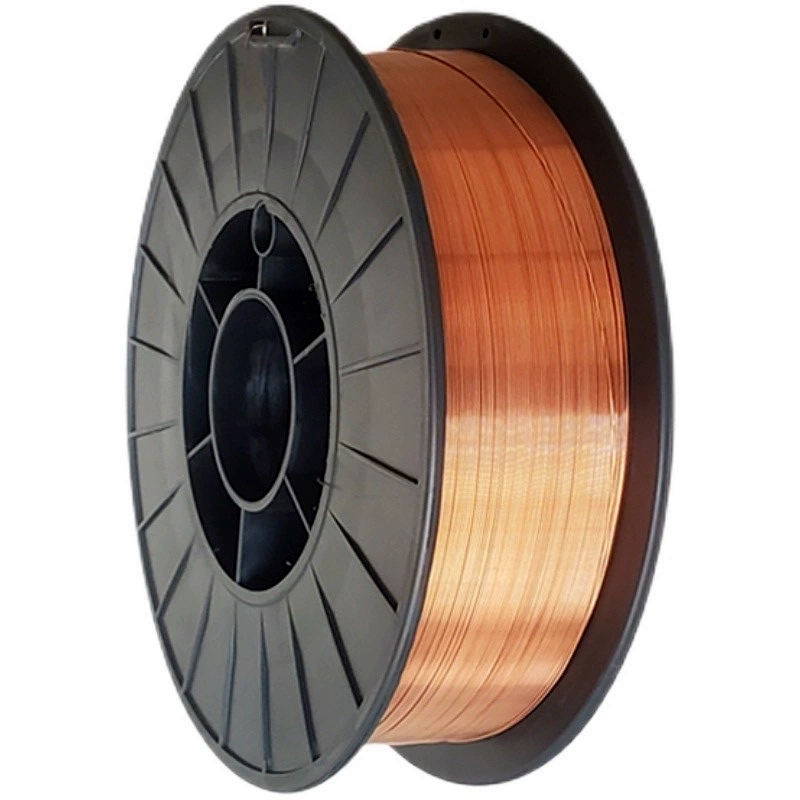

Product& Packaging Parameters

| Model of Welding Wire | φ0.8 | φ1.0 | φ1.2 | φ1.6 |

| Welding Current | 50-100A | 50-220A | 80-350A | 170-550A |

| Gas Flow | 15 | 15-20 | 15-25 | 20-25 |

| Description of Welding Wire | Strong resistance to oxidation and oil stains on the surface of base material, low stomatal sensitivity | |||

| Application | 1. Welding of various 500MPa tensile strength grade structural steel components. | |||

| 2. Welding of various 500MPa tensile strength grade plates and pipes. | ||||

| Diameter(Φ) | Weight(Kg) | Parameter |

| Solid Core 0.8 | 15Kg | 15Kgs/Box=1Roll |

| 84 Rolls(1260Kgs)/Pallet | ||

| Solid Core 1.0 | 20Kg | 20Kgs/Box=1Roll |

| 84 Rolls(1680Kgs)/Pallet | ||

| Solid Core 1.2 | 20Kg | 20Kgs/Box=1Roll |

| 84 Rolls(1680Kgs)/Pallet | ||

| Solid Core 1.6 | 20Kg | 20Kgs/Box=1Roll |

| 84 Rolls(1680Kgs)/Pallet | ||

| Flux-cored 1.0/1.2 | 15Kg | 15Kgs/Box=1Roll |

| 84 Rolls(1680Kgs)/Pallet |

At present, Honglu has over 40 fully intelligent and automated production lines for welding wires, mainly producing solid core welding wires, submerged arc welding wires, etc. Among them, there are 36 production lines for continuous plating and gas shielded welding, 3 production lines for submerged arc welding, and 1 production line for flux cored welding wire, with an annual production of 200000 tons of welding wire.

In terms of raw materials, Honglu welding wires use high-quality raw materials from large steel mills such as Qinggang and Hegang to ensure the high quality of products.

In terms of production process, we adopt the most advanced China production process and a fully enclosed, pollution-free copper plating production line with internal circulation.

Under fully automated and intelligent production equipment, the running speed of each production line can reach 30 meters/second, reaching the most advanced international level.

Now, Honglu Welding Wires are widely used in fields such as ships, boilers and pressure vessels, bridges, railways, locomotives and vehicles, steel structures, petroleum, chemicals, metallurgy, high-rise buildings, and various mechanical manufacturing...