Wuhan Dongfeng Avenue Rapid Transformation Project

This project is located in Wuhan Economic and Technological Development Zone, the scope of the project starts from Wangjiazui Interchange of the Third Ring Road in the north and arranges from northeast to southwest, and ends at the Fourth Ring Road under construction. Design starting mileage KO +692, design ending mileage K6 +500, the total length of reconstruction 5808 meters. Among them, the bridge local length 5808m, up and down ramps 4 groups, the bridge length of 14.6 kilometers, a total investment of 5.8 billion yuan, the bridge width of 41 meters, bidirectional 6 lanes, the use of steel amounted to 5000 tons.

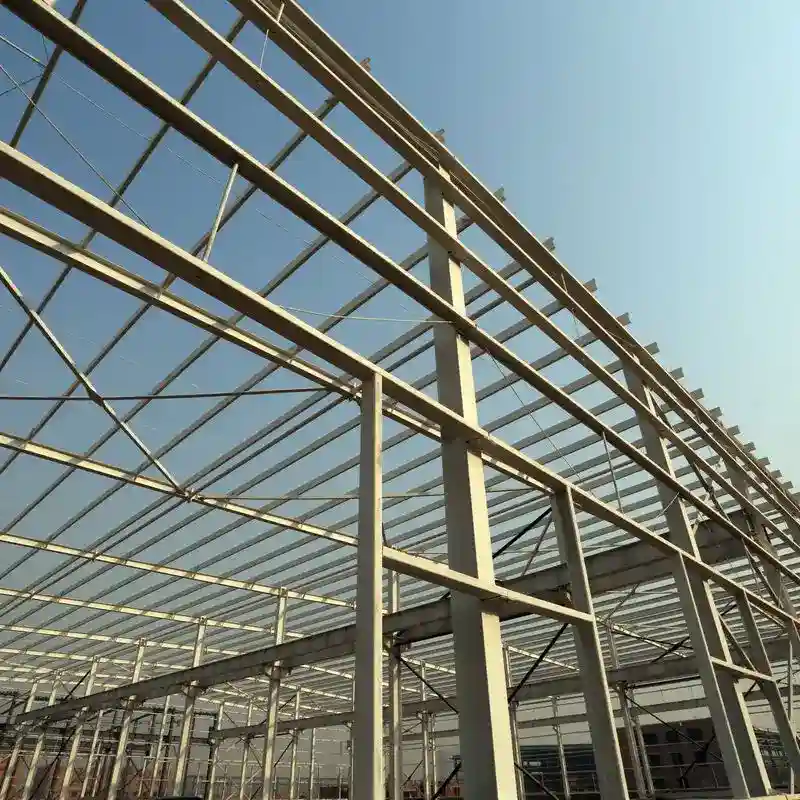

Construction Process Introduction:

Dongfeng Avenue (G318) rapid transformation of the second phase of the main line of the project all for the viaduct, east of Dongfeng Avenue (K6 +500) west to Wuhan West ramp near the mouth (K13 +950), a total length of about 7.14 km standard section of the bridge width of 33 m. The bridge superstructure using prestressed steel reinforced concrete cast-in-place box girder, in the section of the cross-junction with the use of steel box girder; substructure piers and columns of reinforced concrete micro-curved double-limb piers, connected by prestressed reinforced concrete tie beams, pile foundation using bored piles. The substructure piers are reinforced concrete micro-curvilinear double-limbed piers, connected by prestressed reinforced concrete tie beams, and the pile foundation adopts drilled pile foundation. The height of the piers is about 9.0~24.9 m, the width of the tie beams is 1.9~2.5 m, the height at the center is 1.7~20 m, and the total number of piers of the mainline bridge is 191.

According to the overall road design program, this project is an urban expressway, the starting point of the route is located in the third ring road Wangjiazui interchange, from northeast to southwest layout, in turn, across the Prince of Hubei Road, Xinmin River, Triangle Lake Road, Checheng Road West, Shenlong Avenue, Chaoyang Avenue, Checheng Avenue, Checheng Road South, and other intersecting rivers and roads. Route length of about 5808m, the main road using elevated bridge structure form, two-way eight-lane standard section of 33m wide bridge width arrangement 33m = 0.5m (crash wall) +15.5m (motorway) +1.0m (central divider) +15.5m (motorway) +0.5m (crash wall), for the eight lanes of the main line of the elevated + six lanes of the ground in the form of auxiliary roads. In the up and down ramp bridge position of the main bridge widening to 41m51m. the whole line of the main bridge length of 5.808km. the main line elevated on both sides of the arrangement of 4 pairs of parallel on and off the road, respectively, located in the Wanda Plaza, Xianglong Times Square, Dongfeng Electric Vehicle Industrial Park and Checheng South Road section.

The mainline bridge of Dongfeng Avenue has a span of 30m, and the bridge generally adopts 2 to 4 holes, each of which is 51 to 132 meters long. The main span of 50~89m steel continuous beam is used at the intersection of Taizi Hubei Road, Xinmin River, Delta Lake Road, Checheng West Road, Shenlong Avenue, Chaoyang Avenue, Checheng Avenue, Checheng South Road, and the rest of them are all equal cross-section prestressed concrete continuous beams with about 30m span.

Wuhan Dongfeng Avenue Rapid Transformation Phase II Project steel box girder erection construction process, in order to minimize the impact on the existing underpass structure, steel box girder construction support set in the underpass outside, so that the maximum longitudinal steel box girder erection of 30.5m long, in order to facilitate the transportation of steel girder segments, the use of longitudinal subsections, transverse sub-parts of the program, transported to the site of the bridge site on-site welding, the use of two crawler cranes to lift the erection of the program. Program erection.

Wuhan Dongfeng Avenue rapid transformation of the second phase of the project piers using reinforced concrete micro-curved columnar double-limbed piers, through the pre-stressed reinforced concrete tie beam connection, pier types, elegant posture and beautiful shape. Pier height of about 9.0 ~ 24.9 m, beam width of 1.9 ~ 2.5 m, the center of the height of 1.7 ~ 2.0 m, in order to ensure the quality of concrete pouring, the use of a casting molding program. This project has designed an integrated casting support for the pier, column and tie beams, which has completed the construction task safely and efficiently.