The Third Generation Of Roof/Floor Deck Plate Steel Bar Truss

Back Ground:

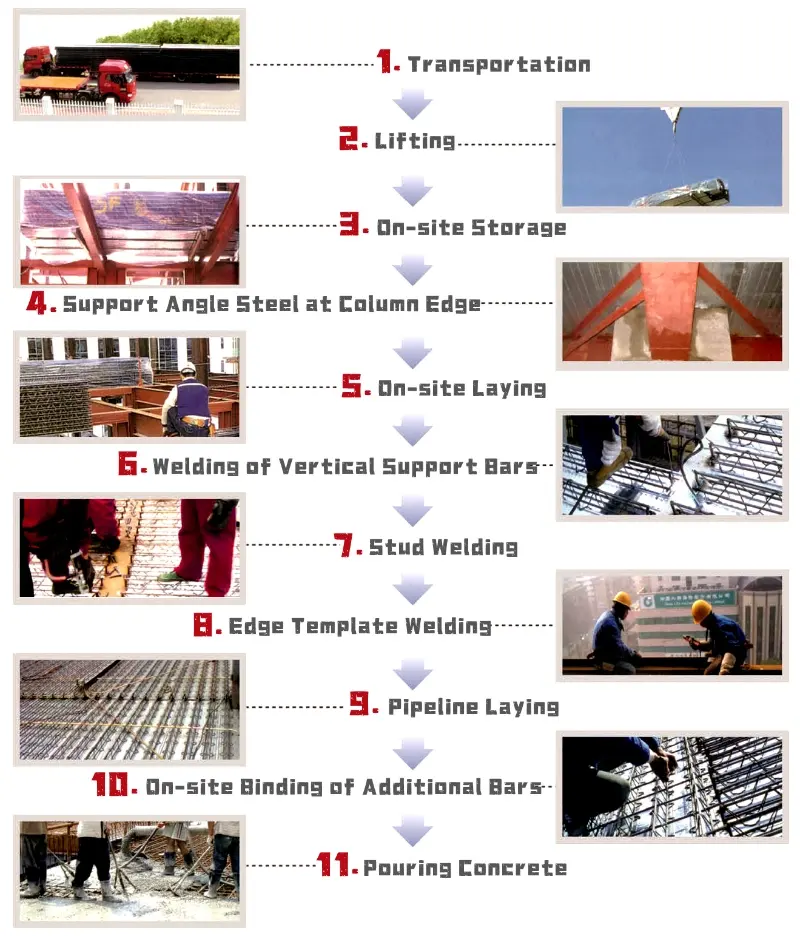

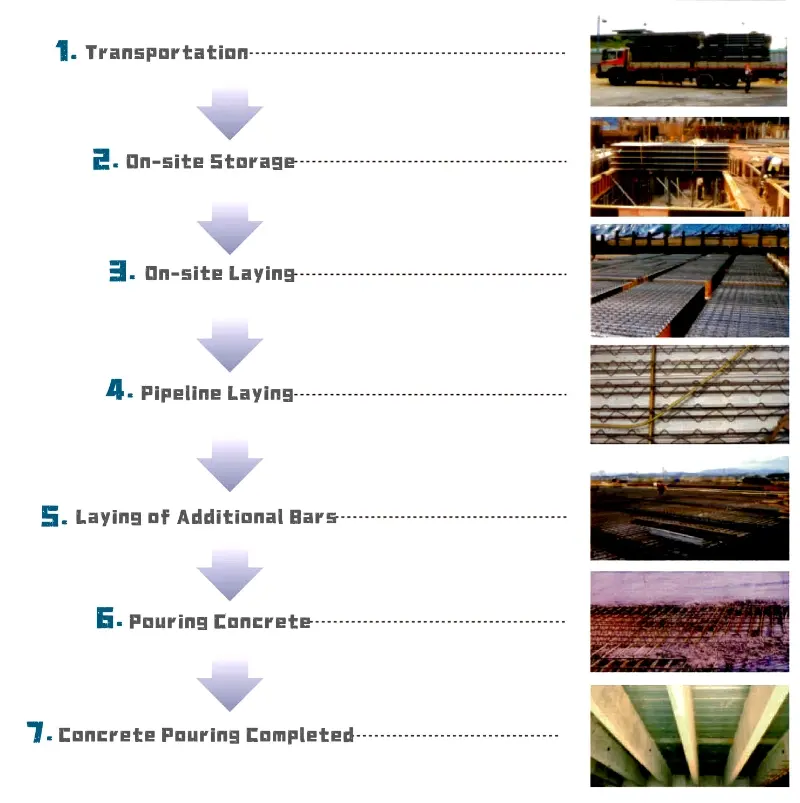

With the rapid development of multistorey and high-rise steel structure buildings, higher requirements on shortening project duration. Steel structure components’ industrialization greatly shorten the construction period, the construction method of floor plate is an important factor affects duration. Too high arris of slab for the first generation and second-generation pressure plate lead to buildings’ net height reduced and under-floor surface uneven, Bi-board design lead to difficult construction and cumbersome banding, bar spacing and concrete cover thickness is difficult to control, also, serious fire and corrosion defects and other problems must be solved. The third generation steel truss floor plate not only includes advantages of the previous two generations steel floor plate and cast-in-place slab, but also take full advantages of steel construction like short construction period, easy controlling construction quality, etc. Highly recognized and praised by the market.

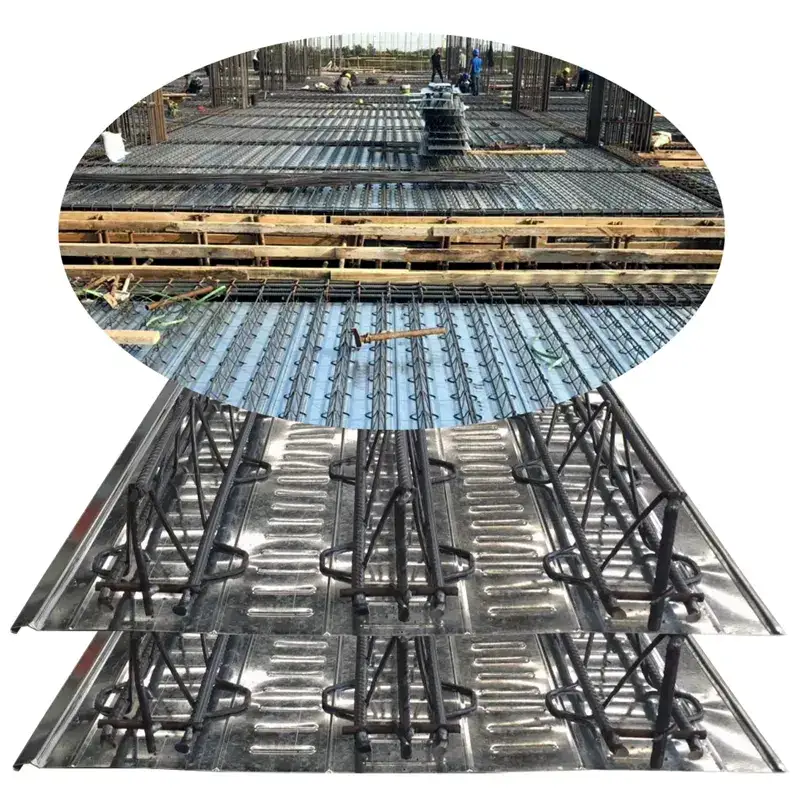

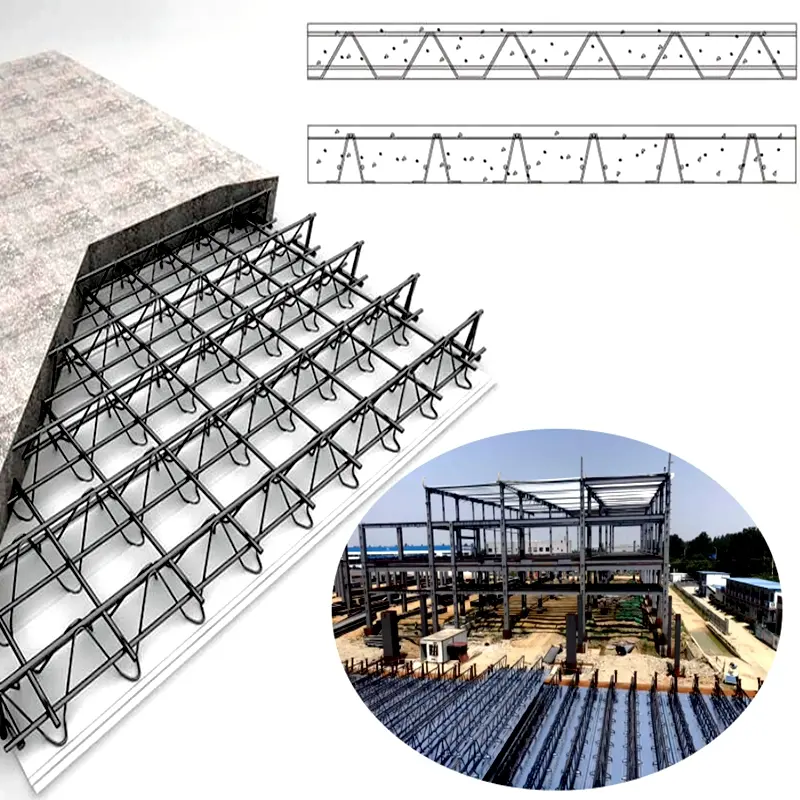

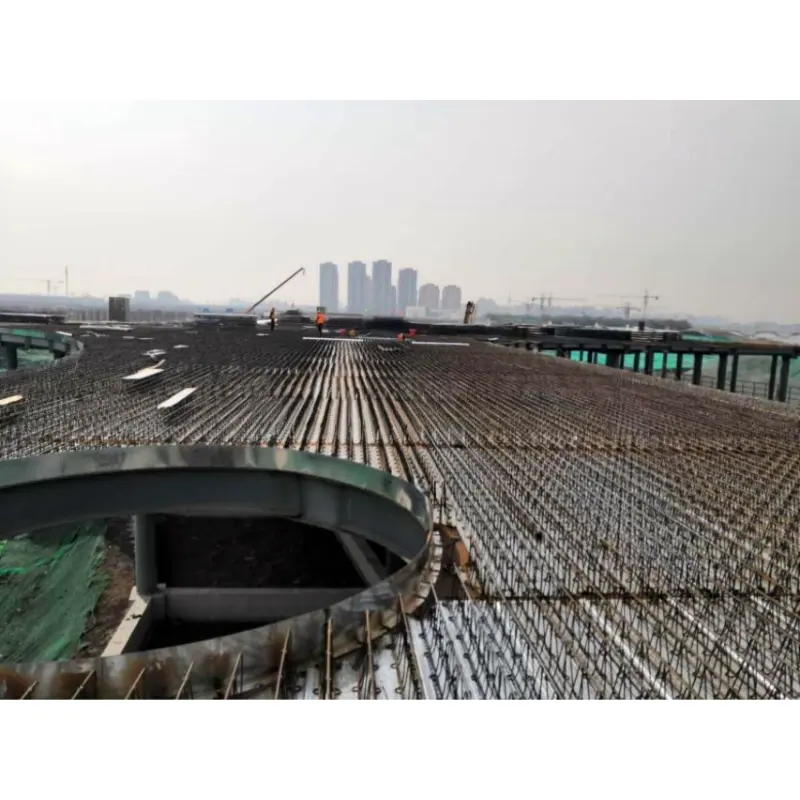

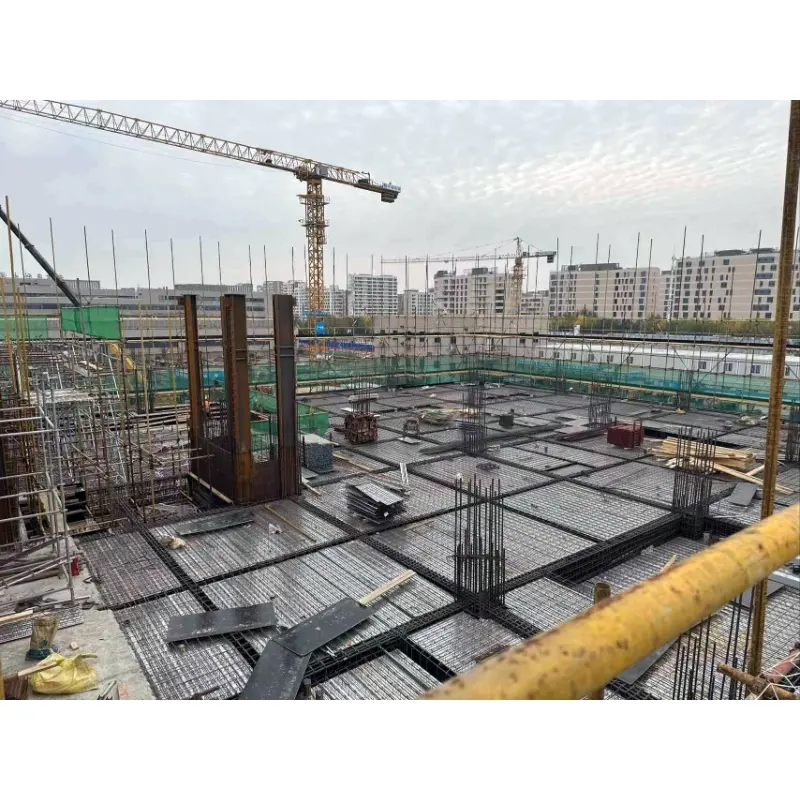

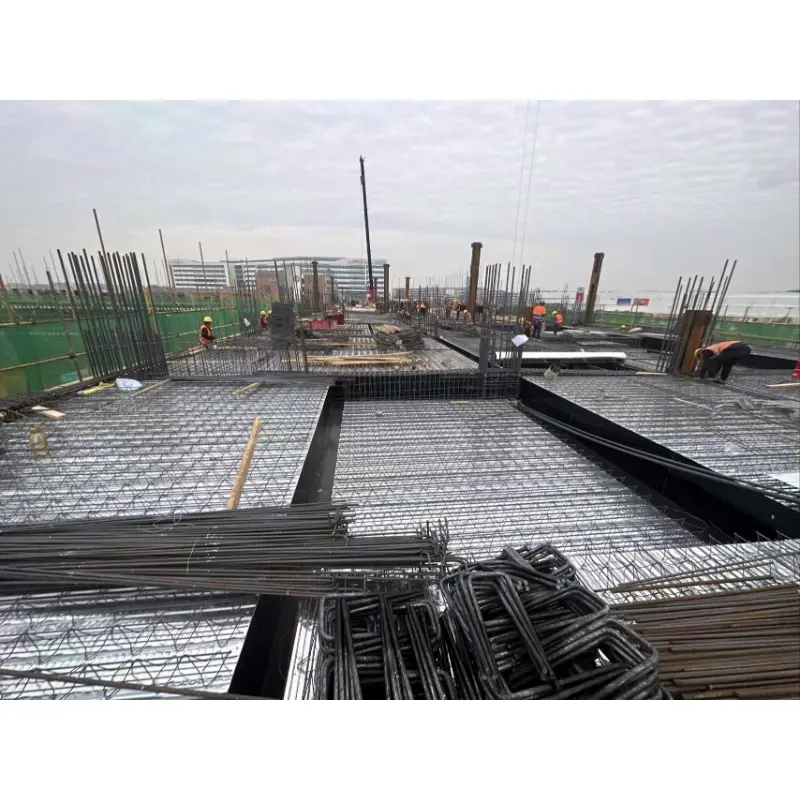

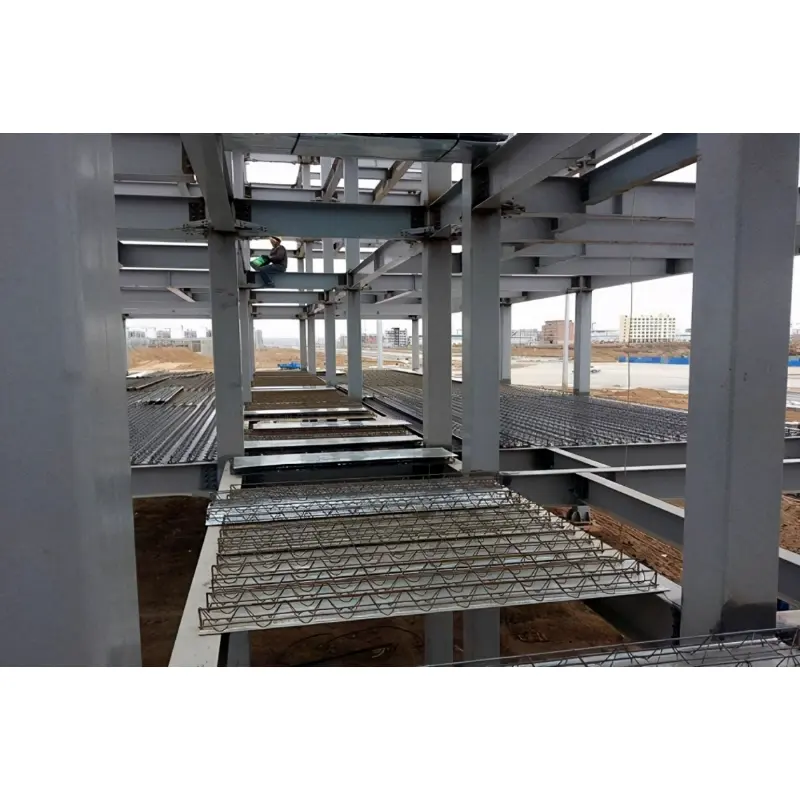

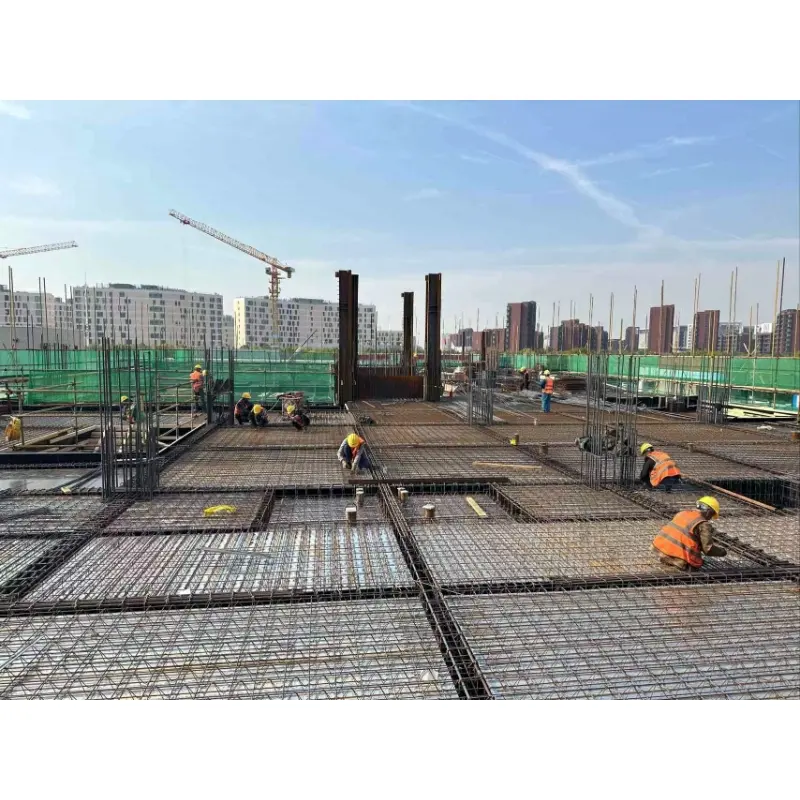

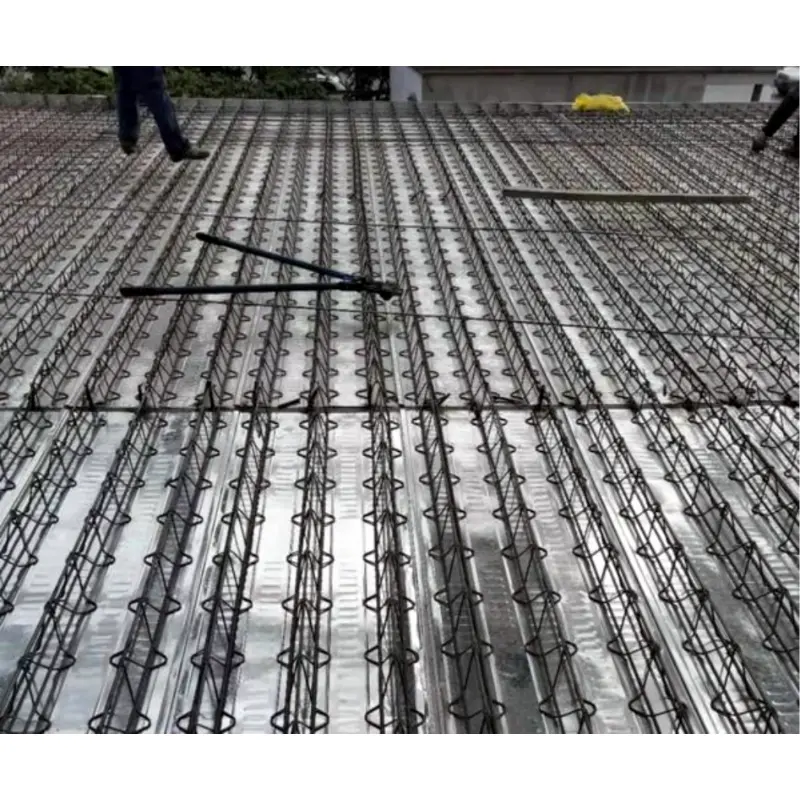

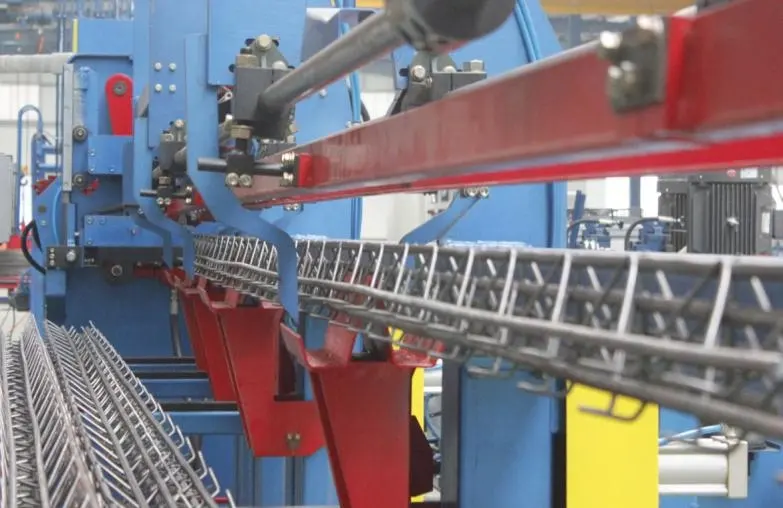

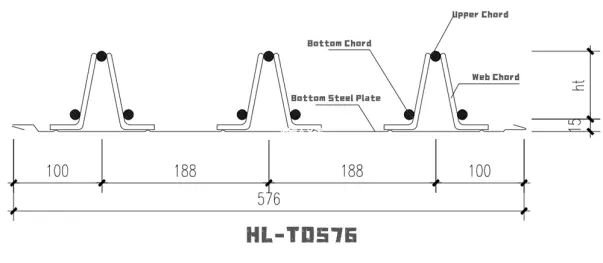

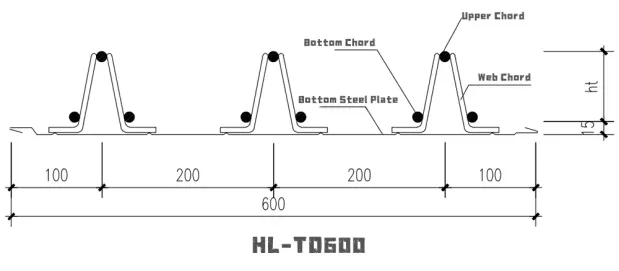

Honglu's third-generation steel truss floor support plate is a composite floor slab that processes steel bars into steel bar truss in factory, and welds steel bar truss with galvanized profiled steel plates into one. During the construction phase, the steel truss floor support plate can withstand the construction load and be directly laid on the beam, concrete can be poured by performing simple steel reinforcement engineering. Due to completely replacing the traditional template function, the traditional template installation and dismantling engineering and related costs have been reduced, greatly improving the efficiency of floor construction while reducing the overall cost. It belongs to a new type of economic, energy-saving, environmentally friendly, efficient, and safe building material.

Till now, Honglu has 40 production lines of Steel Bar Truss in production sites of Hefei, Guoyang, Tuanfeng, etc, with Large production capacity and complete specifications.

Features:

- Rational force mode, convenient construction, environmental protection, shorten construction period greatly.

- Flat bottom plate, high net height, consistent two-way floor stiffness, good seismic performance.

- The bottom steel sheet does not participate in the force, needn’t fire and anti-corrosion coatings, namely security and economy.

- Bars spacing and thickness of concrete cover are easy to control.

- Bidirectional plate design and construction is simple, suitable for large-span floor;

- Rational steel galvanizing layer and reliable stud welding, ends needn’t penetration welding, enhance floor shear force ..

- Compared with traditional concrete slab, needn’t formwork, form-removal, steel banding and other complicated construction process, greatly improving the speed of floor construction, especially for high-rise buildings…

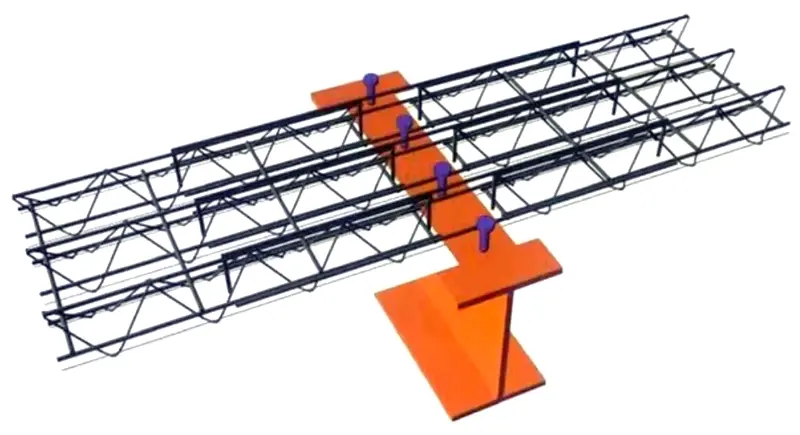

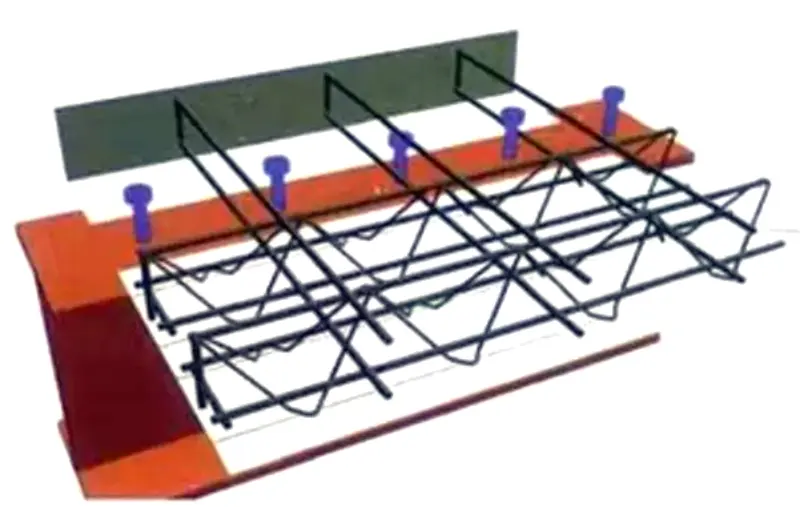

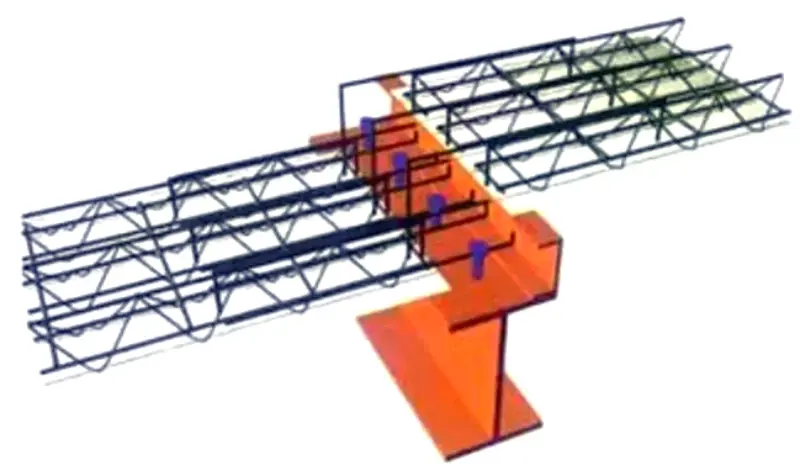

Connection Node Diagram Of Steel Truss:

Connection of steel truss along the direction of main load-bearing reinforcement

Connection of steel truss perpendicular to the direction of load-bearing reinforcement

Plate edge node

Elevated connection at height difference of floor slab

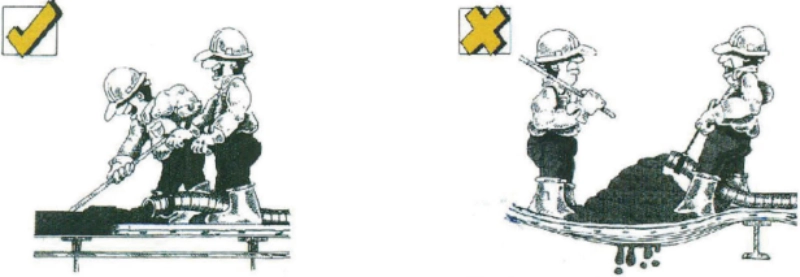

When pouring concrete, care should be taken to avoid excessive accumulation of concrete and the impact caused by pouring concrete

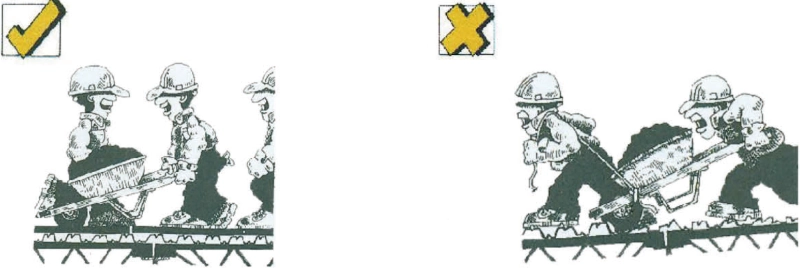

Before pouring concrete, any construction on the completed surface of the floor support plate should absolutely prohibit damaging the cross-sectional shape of the floor support plate to avoid reducing its load-bearing capacity.

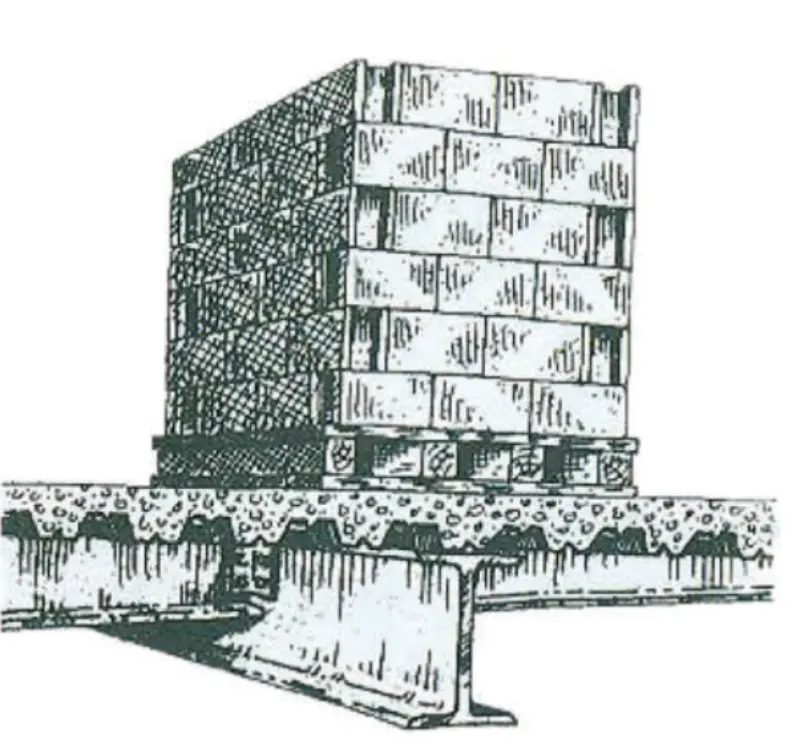

After pouring concrete, if materials need to be stacked on the floor, they should be supported by pallets to avoid concentrated load and placed above the main structural members.