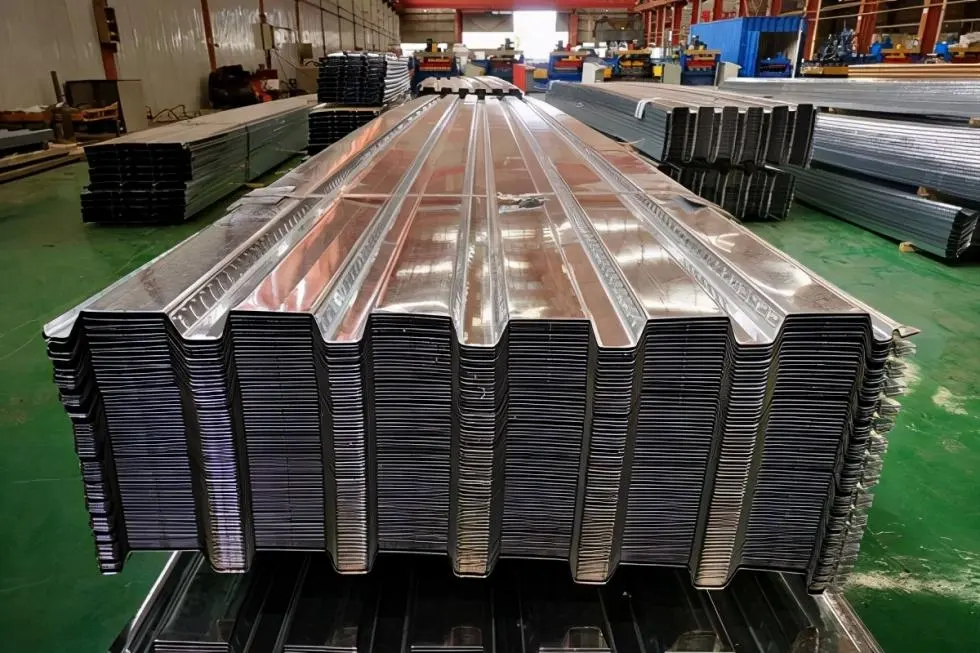

Load Bearing Decking Plate for Steel Structure Building Floor

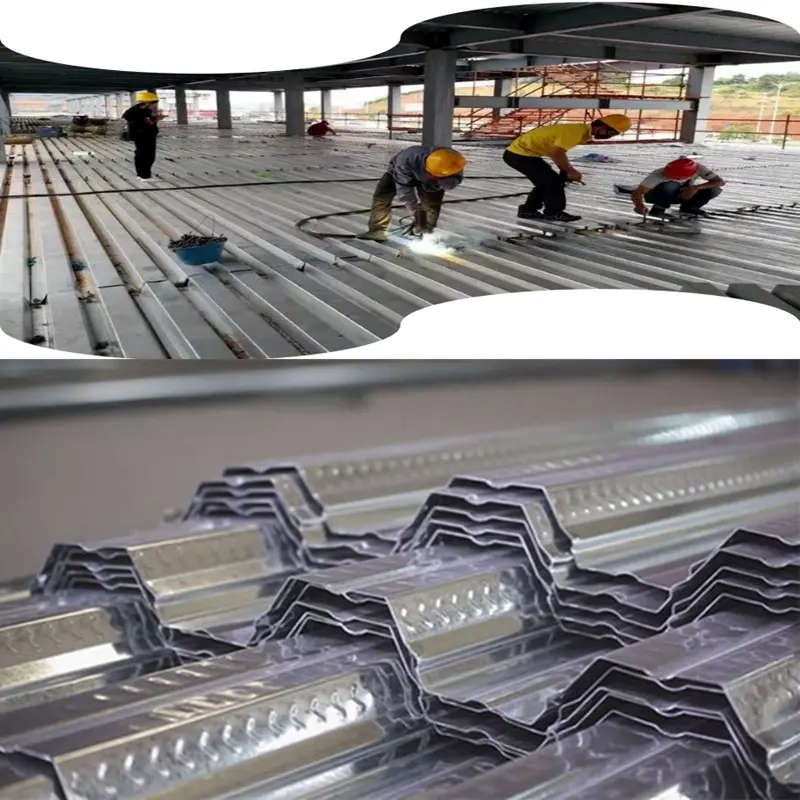

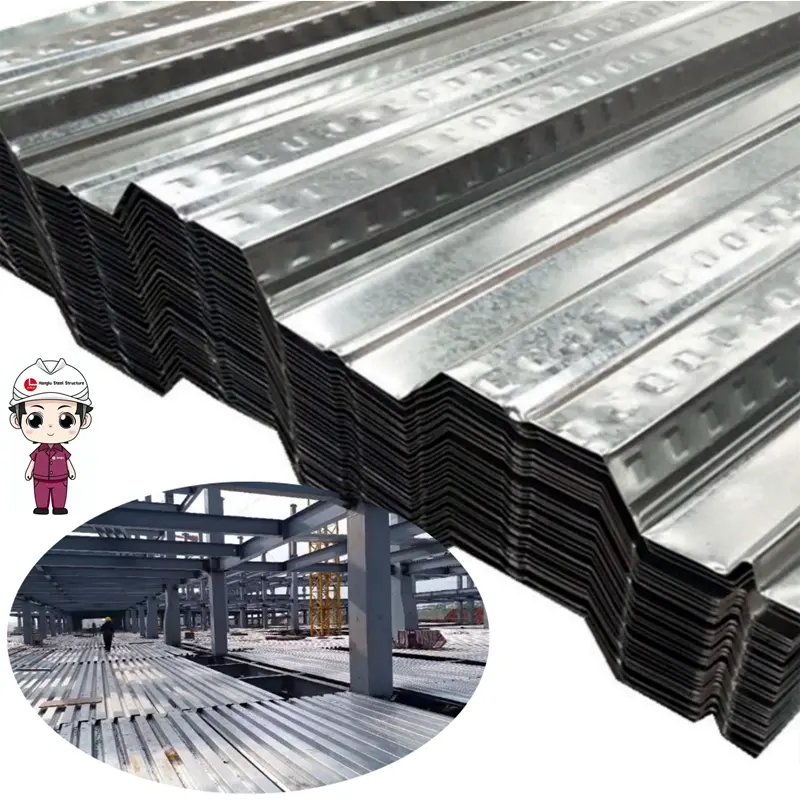

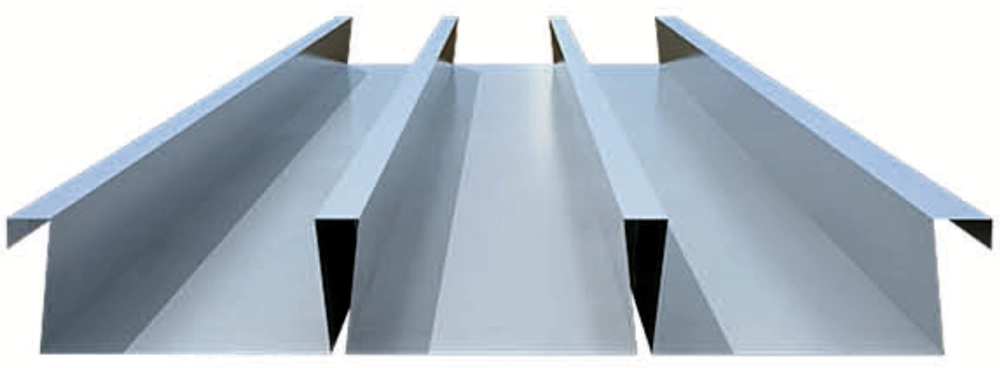

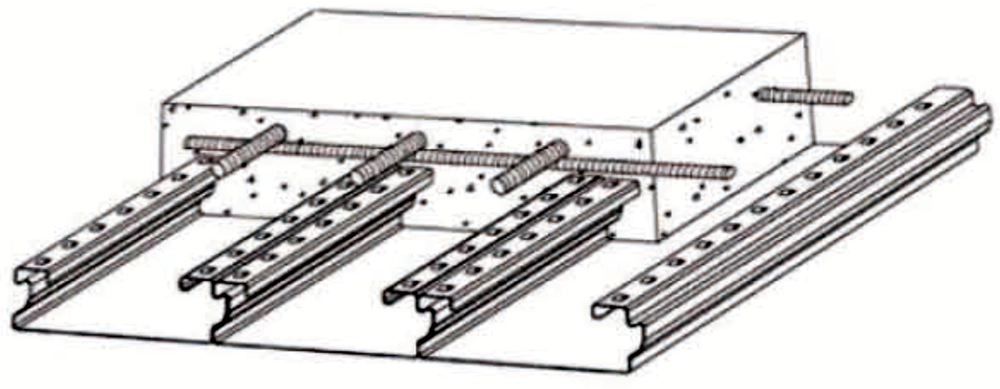

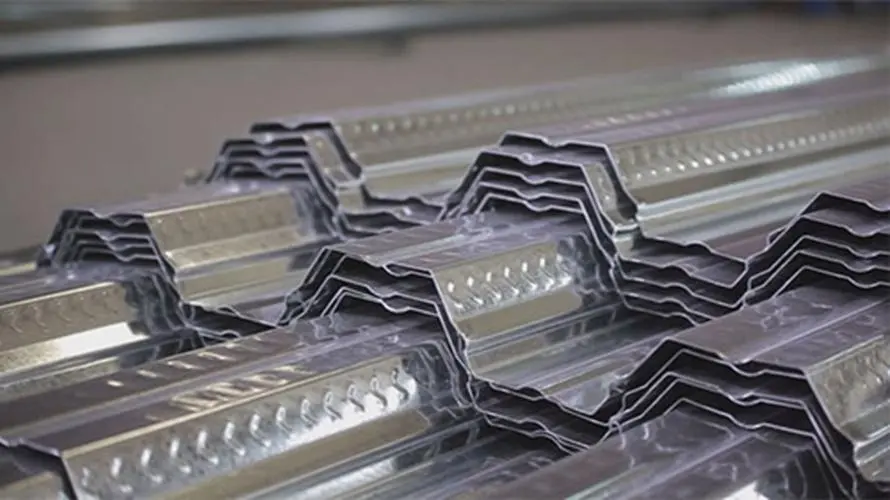

Honglu Load-Bearing Floor Decking Plate is made of galvanized steel plate and formed by rolling and cold bending. Pouring concrete after construction laying, and jointly acting with concrete to form a floor as a whole. It is second only to the main part of beam pillar in steel structure projects, and is used as permanent support formwork of floors.

Performance:

Light weight, high strength, high rigidity, good corrosion resistance, strong seismic resistance, good fire resistance, convenient construction, easy to update, and simultaneously meeting the energy-saving, environmental protection, and safety requirements advocated by the state.

Advantage:

* Save a lot of temporary templates, save all or part of the template support.

* Used as tensile steel bars to reduce the production and installation of steel bars.

* Reduce the amount of concrete used and reduce the permanent load on the structure, suitable for high-rise buildings.

* Save a lot of labor for transportation, stacking, installation, and reducing the workload.

* Convenient for laying communication, power, heating and other pipelines, and can be paved with materials such as insulation, sound insulation, heat insulation, vibrations, etc. to improve floor performance.

* Fully utilize the good tensile strength and ductility of steel, as well as the excellent compressive strength and greater stiffness of concrete.

* Provide multiple work platforms to achieve three-dimensional operations, accelerate progress, shorten construction period, and reduce comprehensive costs.